As we move towards 2025, the landscape of technology trends is rapidly evolving, particularly in manufacturing sectors that are increasingly reliant on innovative materials like Perforated Copper Sheet. According to a recent industry report by MarketsandMarkets, the global market for perforated metals is expected to reach USD 2.12 billion by 2026, growing at a CAGR of 6.7% from 2021. This growth is largely attributed to advancements in processing techniques and a surge in applications across various industries, including construction, automotive, and electronics. As manufacturers strive to achieve greater efficiency and sustainability, the demand for high-quality, energy-efficient, and aesthetically appealing materials is on the rise. The phrase "精工细造,中国制造,服务世界" reflects the commitment to excellence and global service that defines this trend, calling for an exploration into the latest innovations in Perforated Copper Sheet technology that can elevate product performance and meet the demands of the modern market.

As we look forward to 2025, the production of perforated copper sheets is set to be transformed by innovative technologies that aim to enhance efficiency, quality, and sustainability. Emerging advancements such as automation in manufacturing processes and the integration of artificial intelligence for quality control are reshaping the landscape. These technologies promise to minimize waste and optimize the use of resources, making perforated copper sheets a more eco-friendly option for various industries.

Moreover, innovations in material science are leading to the development of more versatile and durable copper alloys. These new materials not only extend the lifespan of perforated products but also increase their adaptability for unique applications in fields ranging from architecture to electronics. By leveraging these cutting-edge technologies, manufacturers can meet the ever-evolving demands of the market while maintaining a commitment to sustainability and performance. The future of perforated copper sheets looks bright, with advancements poised to drive significant changes in production techniques and product capabilities.

This chart illustrates the projected advancements in key technological trends that impact the production of perforated copper sheets by 2025. The data reflects how emerging innovations are expected to affect efficiency, sustainability, and production capabilities.

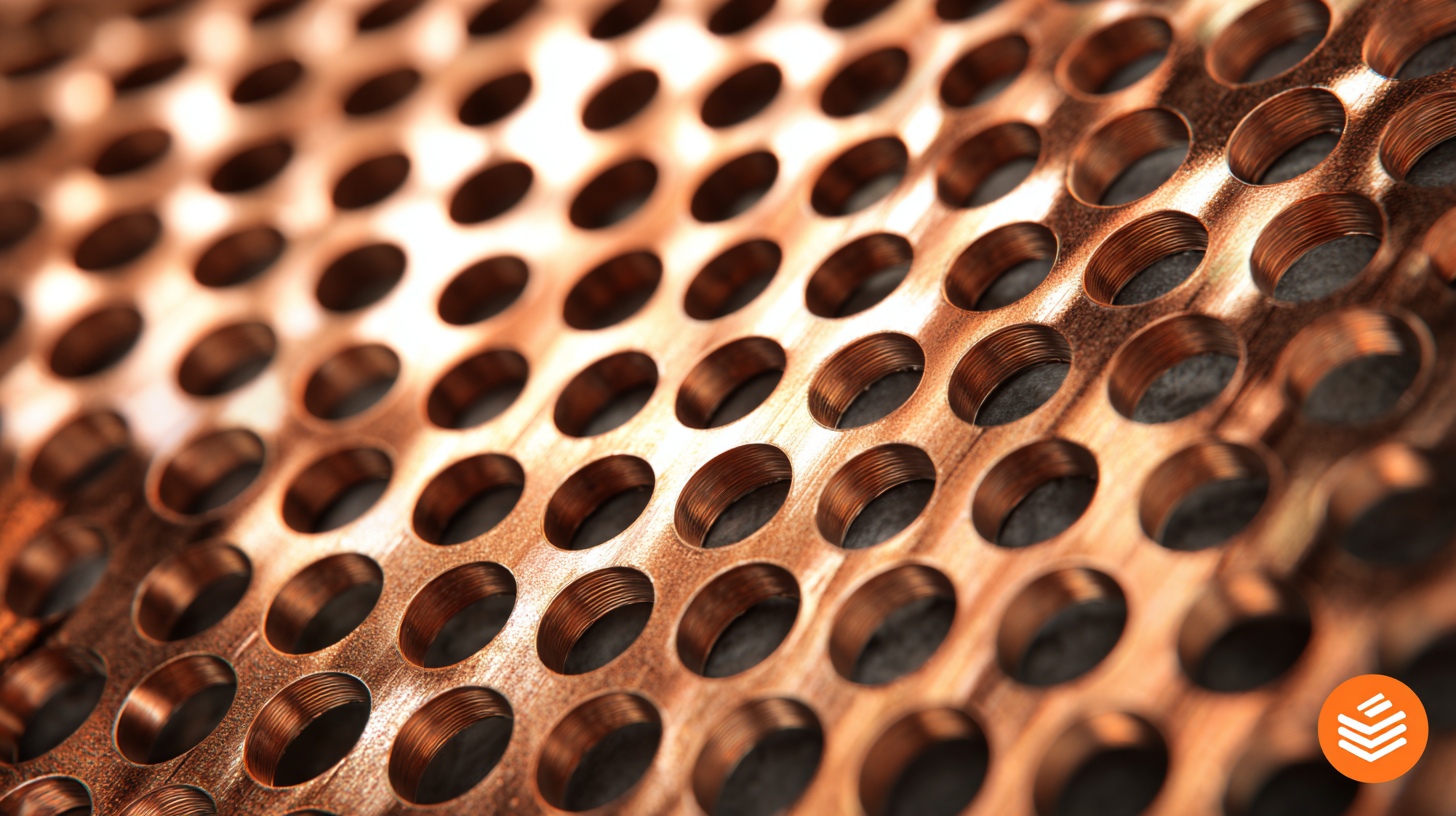

Perforated copper sheets are gaining traction across various industries due to their versatile applications and unique properties. In the architectural realm, these sheets are increasingly being utilized for aesthetic facades and exterior designs, offering both functionality and modern appeal. The perforations not only allow for natural light to filter through but also enhance ventilation, making them ideal for sustainable building practices. Designers appreciate their ability to create striking visual patterns while maintaining structural integrity.

In the manufacturing sector, perforated copper sheets are essential for producing various components, particularly in the automotive and electronics industries. Their conductive properties make them suitable for applications requiring efficient heat dissipation and electromagnetic shielding. Additionally, perforated copper sheets are often used in filtration systems and soundproofing materials, capitalizing on their durability and lightweight characteristics. As innovation continues to drive their evolution, companies are exploring new techniques to enhance their performance, ensuring that perforated copper sheets remain at the forefront of technological advancements.

| Application Area | Innovation Type | Benefits | Industry Sector | Projected Growth (2025) |

|---|---|---|---|---|

| Architecture | Sustainable Design | Enhanced aesthetics and durability | Construction | 15% CAGR |

| Electronics | Electromagnetic Interference Shielding | Improved product longevity and performance | Consumer Electronics | 12% CAGR |

| Automotive | Weight Reduction | Increased fuel efficiency | Transportation | 10% CAGR |

| HVAC Systems | Heat Exchange Optimization | Reduced energy consumption | Building Services | 18% CAGR |

| Art and Design | Creative Installations | Unique visual effects | Cultural Sector | 25% CAGR |

As the demand for sustainable manufacturing practices continues to rise, the copper sheet industry is making significant strides towards eco-friendly innovations. A report by the International Copper Association highlights that the production of copper sheets can now be optimized to minimize waste and energy consumption, leading to a reduction in carbon emissions by approximately 20% over the past decade. These advancements not only enhance the efficiency of manufacturing processes but also contribute to the overall sustainability goals of industries worldwide.

Furthermore, many manufacturers are adopting closed-loop systems, a practice where waste materials are repurposed within the production cycle. According to a recent study published by the Copper Development Association, these systems can recover up to 95% of scrap copper, turning potential waste into valuable resources. This shift not only reduces landfill dependency but also supports the circular economy, offering a blueprint for sustainable practices in the metal industry. By investing in these eco-friendly technologies, companies can position themselves as leaders within the competitive landscape while meeting growing consumer demand for responsibly sourced products.

As industries advance, the application of new coating techniques is becoming increasingly essential for enhancing the performance of various materials, including perforated copper sheets. In the realm of battery production, innovative coating methods are projected to drive market growth significantly, with a forecasted increase from USD 712.4 million in 2025 to USD 2.15 billion by 2033. These advancements not only contribute to the energy density and scalability of batteries, but also pave the way for more sustainable practices in manufacturing processes.

In addition, emerging eco-friendly coating techniques have shown promise across multiple sectors, from food preservation to construction. For instance, the implementation of thermochromic coatings in smart windows offers the potential to dynamically regulate heat gain, thereby reducing energy consumption in buildings. These innovations highlight a growing trend toward sustainability and efficiency, which is crucial in today’s environmentally conscious market. By leveraging these cutting-edge coating techniques, manufacturers can improve performance while aligning with ecological goals and meeting consumer demands for more sustainable products.

As we look towards 2025, the demand for perforated copper solutions is anticipated to grow significantly on a global scale. Industries ranging from construction to electronics are increasingly recognizing the unique properties of perforated copper sheets, including their excellent conductivity, durability, and aesthetic appeal. This versatile material not only plays a crucial role in enhancing functionality but also adds a visually pleasing element to various applications. Understanding and leveraging these future market demands will be essential for companies aiming to remain competitive.

Emerging trends indicate that businesses are seeking innovative ways to integrate perforated copper sheets into their projects. For instance, the rise of sustainable architecture emphasizes the use of materials that are both functional and environmentally friendly. Perforated copper, with its recyclable nature and long lifespan, fits perfectly within this framework. Additionally, the evolving landscape of smart technologies is driving the need for improved thermal management solutions, where perforated copper plays a pivotal role. As global markets evolve, staying aware of these shifts will allow manufacturers and consumers alike to embrace the full potential of perforated copper innovations.