In the ever-evolving landscape of global manufacturing, the materials we choose can significantly impact efficiency, cost-effectiveness, and sustainability. Among the diverse range of materials available, Perforated Plate Steel has emerged as a game-changer, offering unique advantages that cater to various industrial needs. This innovative material, characterized by its strategic hole patterns, not only enhances functionality but also contributes to improved performance in numerous applications, from construction and architecture to filtration and sound absorption.

Embracing Perforated Plate Steel means leveraging its versatility to optimize manufacturing processes and outcomes. As industries strive for higher standards in production quality and environmental responsibility, understanding the key benefits of this material becomes paramount. In this blog, we will explore five essential advantages of using Perforated Plate Steel that can drive efficiency, reduce waste, and promote a more sustainable manufacturing future. Join us as we delve into how this remarkable material is reshaping the landscape of global manufacturing.

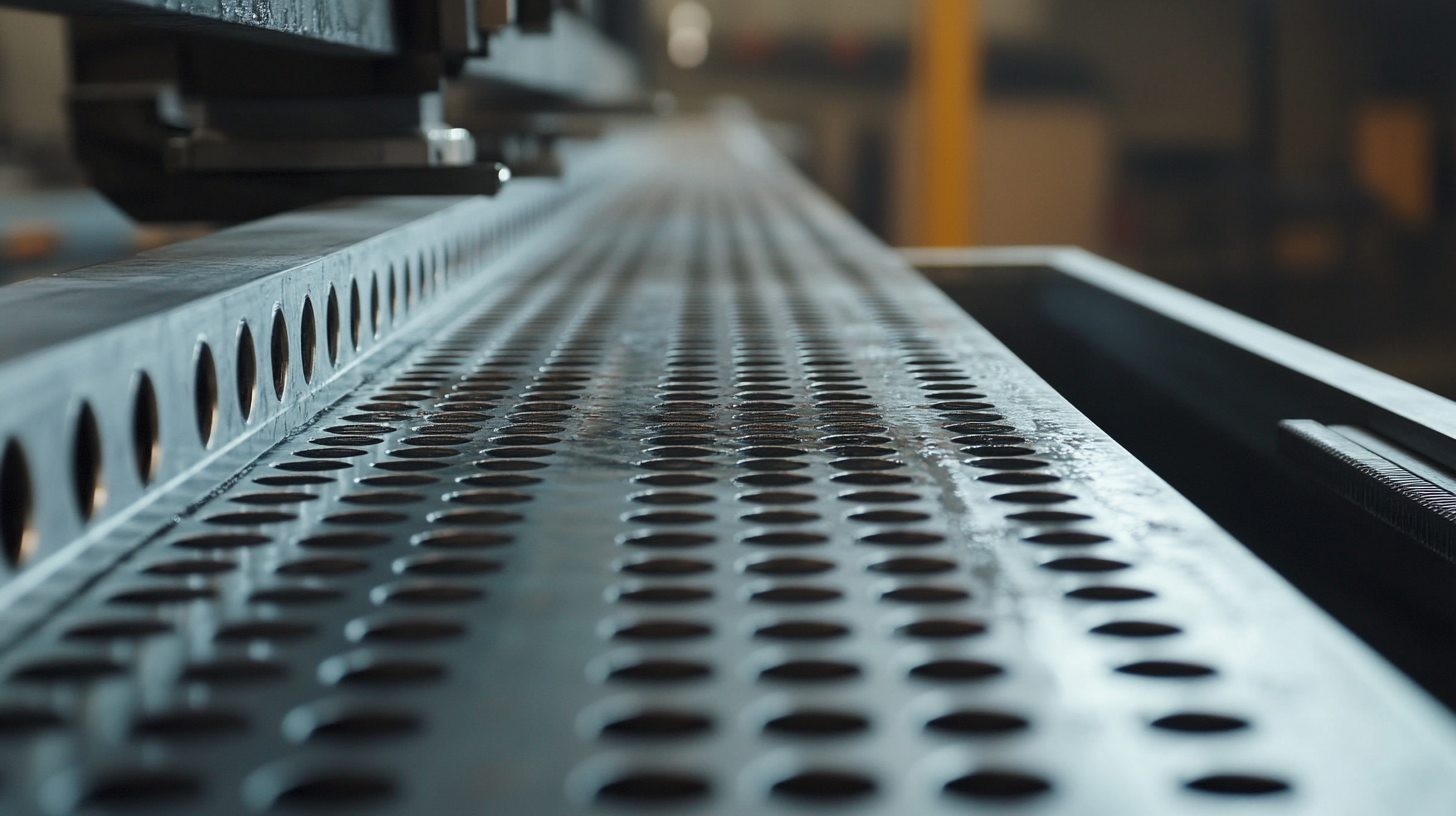

Perforated plate steel has emerged as a game changer in the realm of global manufacturing, particularly due to its innovative design flexibility. One of the most compelling advantages of using perforated plates is their capability to cater to a wide array of applications across various industries. The unique arrangements of holes allow engineers and designers to create lightweight structures without sacrificing strength. This balance is critical for product development, as it enables the creation of components that are not only durable but also resource-efficient.

Incorporating perforated plate steel into product designs also opens up avenues for enhanced aesthetics. The perforation patterns can be customized to meet aesthetic demands while maintaining functionality, allowing manufacturers to produce visually striking products that stand out in the marketplace. This creative freedom can be invaluable in sectors such as architecture and consumer goods, where the look and feel of a product can significantly influence consumer purchasing decisions.

Furthermore, the adaptability of perforated plate steel simplifies the process of prototyping and reducing manufacturing lead times. Designers can quickly iterate on their ideas, producing variations in form and function without extensive retooling. This rapid development cycle not only encourages innovation but also enables manufacturers to respond promptly to emerging market trends, giving them a competitive edge. By leveraging the design flexibility afforded by perforated plate steel, companies can bring more inventive and tailored solutions to the market, thereby advancing their product lines and enhancing their brand identity.

When it comes to global manufacturing, the choice of materials can greatly impact the overall efficiency and longevity of products. One material that stands out in this respect is perforated plate steel. Renowned for its strength and durability, perforated plate steel is increasingly becoming the preferred choice among manufacturers. Its unique structure not only enhances performance but also contributes to a more sustainable manufacturing process.

The strength of perforated plate steel lies in its engineering principles. The design combines steel's inherent toughness with a series of carefully calculated perforations, resulting in a material that can withstand significant loads without compromising structural integrity. This makes it ideal for a variety of applications, from architectural elements to industrial equipment. Manufacturers benefit from reduced maintenance costs and extended product lifespans, thanks to this remarkable strength.

Durability is another key metric driving the adoption of perforated plate steel in manufacturing. Unlike traditional solid steel, the perforated variant exhibits excellent resistance to corrosion and wear and tear. This resilience means that components remain operational in harsh environments, ultimately reducing downtime and enhancing productivity. As industries strive for increased efficiency and lower operational costs, the importance of using materials like perforated plate steel cannot be overstated.

Perforated plate steel has emerged as a key material in global manufacturing, particularly in enhancing cost-efficiency across various sectors. By employing perforated plate steel solutions, manufacturers can significantly reduce their material costs while simultaneously benefiting from improved resource management. The innovative design of perforated plate steel allows for weight reduction without compromising strength, making it an ideal choice for applications ranging from construction to automotive industries.

In the context of residential buildings and passenger vehicles, the transition to perforated plate steel can lead to substantial resource and emission savings. As the recent analysis of material flows indicates, optimizing the use of materials in these sectors not only reduces costs but also promotes sustainable practices. Such efficiency measures align with global goals of climate change mitigation, where demand-side solutions play a critical role in fostering economic growth without imposing heavy environmental burdens.

Moreover, the integration of perforated plate steel in manufacturing supports the principles of a circular economy. By maximizing the use of materials and minimizing waste, companies can contribute to a more sustainable supply chain. This strategic move not only helps in alleviating resource scarcity but also positions businesses favorably in an increasingly eco-conscious market landscape, ultimately driving down operational costs and enhancing competitive advantage.

| Benefit | Description | Cost Savings (%) | Application Areas |

|---|---|---|---|

| Lightweight | Reduced material weight leads to lower shipping costs. | 15% | Automotive, Aerospace |

| Versatility | Can be used in various applications, enhancing resource utilization. | 10% | Construction, Architecture |

| Sustainability | Made from recyclable materials, promoting environmentally friendly practices. | 5% | Manufacturing, Retail |

| Energy Efficiency | Improves airflow and reduces energy consumption in HVAC systems. | 20% | HVAC, Industrial Facilities |

| Aesthetic Appeal | Offers a modern look for buildings and structures, enhancing value. | 8% | Interior Design, Facades |

The manufacturing sector is increasingly recognizing the importance of sustainability, especially with the growing environmental concerns. One innovative solution is the use of perforated plate steel, which contributes to reducing waste and energy consumption. By integrating sustainability metrics into manufacturing processes, companies can harness the benefits of perforated plate steel to enhance their production efficiency and minimize environmental impacts.

Perforated plate steel allows for better airflow and material usage, which significantly lowers energy consumption in various manufacturing applications. Its lightweight nature does not compromise strength, facilitating optimal resource utilization. Furthermore, the digitization of manufacturing practices, such as the incorporation of digital twins, provides real-time data that can be crucial in identifying areas for improvement. By combining production metrics with sustainability goals, manufacturers can innovate processes that promote not only operational efficiency but also eco-friendliness.

In light of global sustainability goals, including the need for sustainable consumption and production practices, the adoption of perforated plate steel and similar innovative materials represents a forward-thinking approach. This aligns with the overarching objective of minimizing waste and energy use—not only benefiting the companies involved but also contributing to the global movement towards a more sustainable future in manufacturing. As awareness of sustainable practices grows, the integration of such materials will likely become a standard in manufacturing strategies going forward.

The global manufacturing landscape is witnessing a notable surge in the demand for perforated plate steel across various industries. This increase can be attributed to the material's versatility, durability, and aesthetic appeal. As companies seek solutions that enhance both functionality and design, perforated plate steel is emerging as an optimal choice to meet these multifaceted needs.

One of the most significant trends driving this demand is the rise of eco-friendly manufacturing practices. Perforated plate steel is lightweight yet robust, allowing manufacturers to reduce material usage while maintaining strength. This not only aligns with sustainability goals but also minimizes transportation costs and energy consumption. Industries such as construction, automotive, and aerospace are increasingly incorporating this material to optimize their operations and contribute to a greener economy.

Additionally, the versatility of perforated plate steel lends itself to various applications, from noise reduction panels in urban environments to filtration systems in industrial settings. As designers and engineers seek innovative solutions, the ability of perforated steel to be customized in terms of hole size, pattern, and material thickness means it can be tailored to specific project requirements. This factor, paired with ongoing technological advancements, solidifies its place in the future of manufacturing.