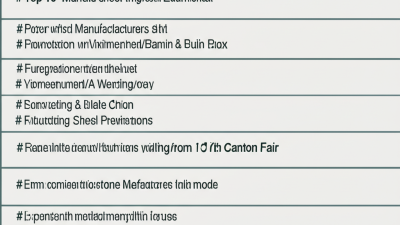

Perforated Stainless Steel Mesh has gained significant attention in various industries. Its unique design offers a blend of functionality and aesthetic appeal. This type of mesh features precise holes, allowing for light and airflow, while maintaining strength and durability.

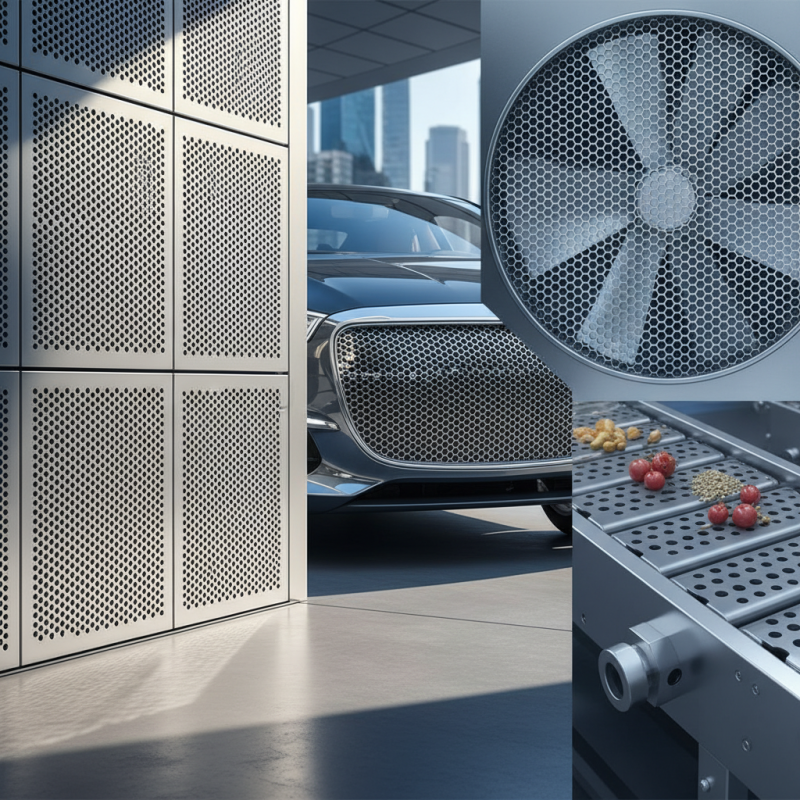

One major benefit is its versatility. Perforated Stainless Steel Mesh can be used in architecture, automotive, and even food processing applications. For instance, it can enhance the appearance of buildings while providing safety and ventilation. Additionally, its corrosion resistance makes it suitable for outdoor use.

However, some may overlook the potential downsides. The manufacturing process can create imperfections that may lead to weaknesses. Understanding these limitations is crucial. Overall, the advantages of Perforated Stainless Steel Mesh are evident, yet reflection on its challenges can lead to better applications and innovations.

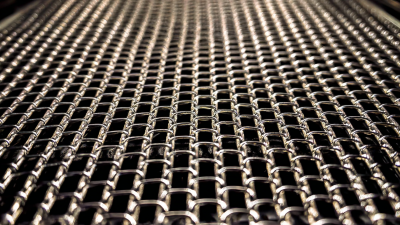

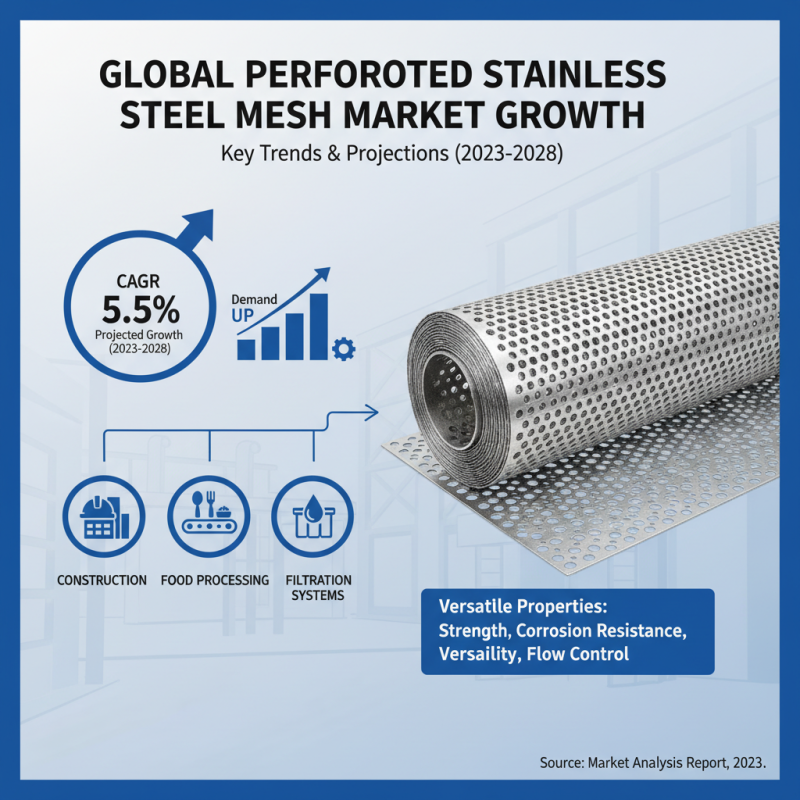

Perforated stainless steel mesh has gained traction in various industrial applications due to its unique properties. According to a recent market analysis, the global demand for perforated metal is projected to grow at a CAGR of 5.5% through 2028. This growth is driven by increased utilization in sectors like construction, food processing, and filtration systems.

One significant benefit is its structural integrity. The mesh's ability to withstand extreme temperatures makes it ideal for high-heat environments. Industries report reduced maintenance costs due to its durability. In the food sector, perforated stainless steel aids in effective air circulation during drying processes. The perforations allow for better energy efficiency, resulting in cost savings.

However, it’s important to consider some challenges. The manufacturing process can produce sharp edges, necessitating proper handling and safety measures. Additionally, the choice of hole size must align with specific application needs. Customers sometimes overlook this, leading to inefficiencies in performance. Therefore, awareness and education on these factors are crucial for optimal usage.

Perforated stainless steel mesh is a game-changer in improving airflow and ventilation. This material allows air to flow freely while providing structural integrity. In spaces such as factories or warehouses, adequate ventilation is crucial. Studies indicate that proper ventilation can enhance air quality by up to 30%. This is significant for worker health.

Moreover, perforated steel can reduce energy costs. The mesh allows for natural airflow, decreasing reliance on air conditioning systems. A report by the International Energy Agency states that well-ventilated spaces can reduce energy use by approximately 15-20%. Not all spaces achieve these savings, though. Some installations might not utilize the mesh effectively, leading to suboptimal airflow.

The aesthetic versatility of perforated stainless steel is another advantage. It serves functional and decorative purposes in architecture. However, not every design maximizes its potential. Some structures miss opportunities for ventilation and light. Awareness of these issues can lead to better design choices in the future. Understanding the benefits of perforated stainless steel mesh is vital for enhancing airflow and creating sustainable environments.

Perforated stainless steel mesh offers numerous advantages, especially its corrosion resistance. This feature makes it an ideal choice for various applications. Stainless steel, by nature, can withstand harsh environmental conditions. It resists rust and deterioration, providing a long-lasting solution. This durability is crucial in industries like construction and food processing.

The unique structure of perforated stainless steel mesh allows for airflow and drainage. This design helps prevent moisture build-up, further reducing corrosion risks. In settings where hygiene is critical, such as kitchens, this property becomes even more significant. However, it's important to remember that the mesh must be maintained regularly. Neglecting upkeep can lead to corrosion over time, diminishing its benefits.

While stainless steel mesh is generally low-maintenance, some challenges remain. The initial cost can be higher than other materials. Yet, over time, the savings from durability and reduced replacements justify this expense. Scrutinizing all aspects of your project is essential. Balancing performance and cost can be tricky but necessary for achieving the best results.

| Benefit | Description | Application |

|---|---|---|

| Corrosion Resistance | Stainless steel mesh is highly resistant to rust and corrosion compared to other materials, making it ideal for harsh environments. | Industrial filtration, marine applications |

| Durability | With its robust construction, stainless steel mesh lasts longer, reducing the need for frequent replacements. | Construction, infrastructure |

| Versatility | Available in various hole sizes and patterns, perforated stainless steel can be tailored to specific requirements. | Architectural features, decorative elements |

| Ease of Maintenance | Cleaning and maintaining stainless steel mesh is straightforward, contributing to lower long-term costs. | Food processing, medical applications |

| Aesthetic Appeal | Perforated stainless steel can enhance the visual appeal of structures while providing functionality. | Interior design, facades |

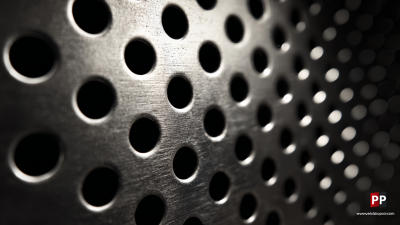

Perforated stainless steel mesh is highly versatile, offering both aesthetic appeal and practical benefits. Its customization options allow for a range of designs and functions. Whether you need a decorative facade or a functional filter, this material can meet your needs.

When considering customization, think about the hole size and pattern. Different arrangements can drastically change the appearance and functionality of the mesh. Various finishes, like polished or matte, can enhance its look. Additionally, custom cuts can be made to fit specific dimensions. This flexibility opens up possibilities for unique projects.

Tip: Always test samples before committing to a design. Sometimes, colors and patterns look different in real life. If possible, review the mesh under varying lighting conditions. Take time to reflect on the intended use. A functional use might detract from the aesthetics you initially envisioned. Balancing beauty and practicality can be a challenge.

Perforated stainless steel mesh is a popular choice across various industries due to its remarkable durability. Studies show that stainless steel is resistant to rust and corrosion, even in harsh environments. For example, in marine settings, where exposure to saltwater is common, stainless steel can last significantly longer than other metals. This resilience contributes to lower maintenance costs over time.

In industrial applications, the mesh maintains structural integrity under stress. A report from the Metal Industries Association highlights that perforated stainless steel can withstand heavy loads without deforming. This feature is crucial in construction and manufacturing. However, it's important to consider the specific environment. Some environments may expose the mesh to unique challenges, such as chemical exposure, which may require special grades of stainless steel.

Not all perforated stainless steel is created equal. Factors such as hole size and thickness can influence longevity. Industry experts suggest evaluating these elements based on application needs. While perforated stainless steel offers many benefits, there can be oversight in selecting the right type for specific conditions. Investing in proper assessment can prevent costly mistakes in the long run.