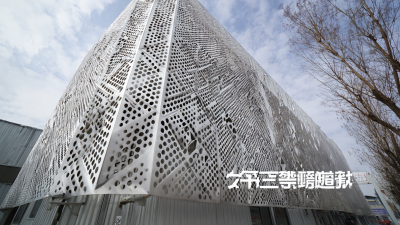

In the construction and architecture industry, the use of "Perforated Metal Screens" has gained significant attention. According to Dr. Emily Johnson, a leading expert in architectural materials, "Perforated Metal Screens offer unique solutions for both aesthetic and functional needs." These screens combine utility with design, enhancing both safety and beauty in projects.

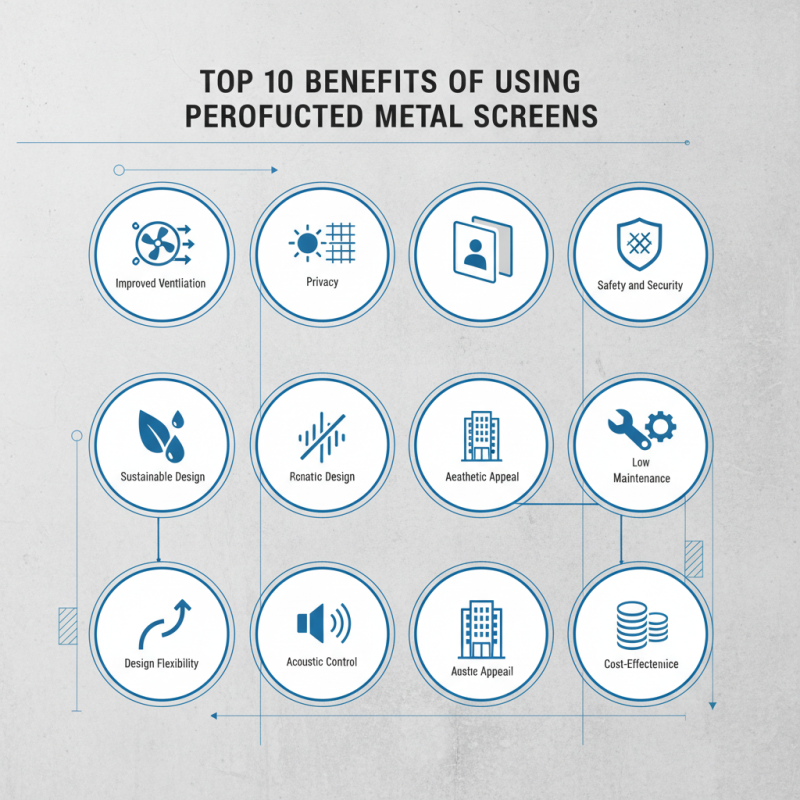

Choosing perforated metal allows for improved ventilation and light while maintaining privacy. Many industries have embraced this innovation, often using it in facades, partition walls, and ceiling designs. However, some applications may not achieve the intended elegance or functionality. Designers must carefully consider the screen’s hole patterns and material types to avoid potential pitfalls.

Color, finish, and thickness all play crucial roles in the efficacy of perforated metal. A poorly executed design can lead to unexpected drawbacks. Therefore, thoughtful planning is essential. As the industry evolves, it's clear that "Perforated Metal Screens" will continue to reshape architectural landscapes while reminding us of the need for creativity and precision.

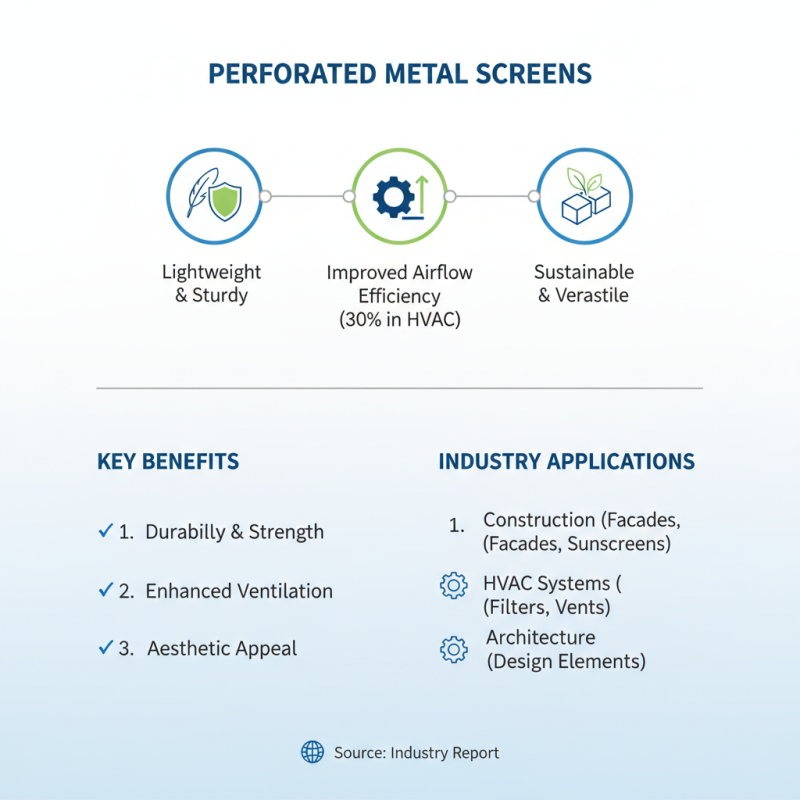

Perforated metal screens are increasingly popular across various industries, offering numerous advantages. One key benefit is their lightweight yet sturdy design. These screens are made from various metals, providing flexibility in application. In construction, they serve as effective ventilation solutions while maintaining structural integrity. An industry report indicates that the use of perforated metal can improve airflow efficiency by 30% in HVAC systems.

Another significant advantage is their aesthetic appeal. Perforated metal screens can enhance the visual design of buildings and products. This has been particularly noted in the architectural sector, where unique patterns can be created for decorative purposes. A study shows that 65% of architects prefer using perforated materials for their projects.

**Tip:** Consider the hole size and pattern when selecting perforated screens. This affects both functionality and look.

In the manufacturing industry, these screens are crucial for filtration processes. With custom designs, they can filter specific particle sizes effectively. However, achieving the right balance between durability and filter efficiency is not always easy. Constant evaluation is needed to assure that they meet operational standards while avoiding unnecessary replacements.

**Tip:** Regular inspection can help maintain performance and prolong the lifespan of perforated screens.

Perforated metal screens are becoming a popular choice in various applications. One significant advantage is their ability to enhance airflow and ventilation. These screens allow air to pass through easily, which is crucial in environments needing proper air circulation.

In industrial settings, using perforated metal can help regulate temperatures. Machines generate heat, and without sufficient airflow, the environment can become stifling. This situation can lead to equipment failures or even hazardous conditions. The perforations in the metal facilitate a constant flow of fresh air while allowing heat to dissipate. However, the size and shape of the perforations must be carefully considered to achieve optimal results. Too small, and airflow can be restricted; too large, and structural integrity may be compromised.

Also, using perforated metal solutions can help reduce energy costs. Traditional ventilation systems often consume excessive energy to maintain airflow. In contrast, perforated metal structures can offer a more natural approach. They lessen the need for mechanical systems. However, relying solely on this solution may not be suitable for all situations. Some areas may still require additional ventilation support for consistent performance.

Perforated metal screens are widely known for their durability and strength. These screens are made from robust materials, which contribute to their long-lasting performance. According to industry reports, perforated metal can last over 40 years in various applications. This means lower replacement costs in the long run. Their resistance to corrosion and impact makes them ideal for both indoor and outdoor uses.

When selecting perforated metal, it’s crucial to consider the thickness and hole size. Thicker sheets generally enhance strength. However, larger holes can offer better airflow. Balancing these factors can be challenging. It’s essential to reflect on the specific application to avoid over-engineering, which may lead to unnecessary expenses.

Tip: Always conduct a stress analysis before installation. This ensures that the chosen perforated screen meets environmental demands. Regular maintenance checks can significantly extend the lifespan of your screens. Consider a yearly inspection, even if the screen appears undamaged. Drawing insights from these points can lead to more informed decisions.

Perforated metal screens offer remarkable aesthetic appeal. Their unique patterns add an artistic touch to various environments. Architects and designers appreciate this flexibility. They can create custom designs that reflect personal or brand identity. The ability to choose hole size, shape, and arrangement allows infinite possibilities.

Using perforated metals can sometimes lead to challenges. For instance, maintenance might be tricky if the design traps dirt and debris. Regular cleaning is essential to keep surfaces looking fresh. Colors and finishes can fade over time, affecting overall appearance. Choosing the right material and coating becomes important for long-term durability.

The play of light and shadow created by perforated screens enhances any space. Natural light filters through, creating inviting atmospheres. This dynamic quality makes them popular for architectural applications. In outdoor settings, they can blend beautifully with surroundings. Perforated metals provide both fashion and function, meeting practical needs while elevating visual appeal.

| Benefit | Description |

|---|---|

| Aesthetic Appeal | Perforated metals offer a unique design that enhances modern architecture and interior spaces. |

| Ventilation | They allow air to circulate freely while maintaining privacy and protection. |

| Light Transmission | Perforated screens can control the amount of light entering a space, creating an inviting ambiance. |

| Design Flexibility | Available in various patterns, shapes, and materials for customizable design options. |

| Durability | Metal screens are resistant to wear and tear, making them suitable for long-term use. |

| Sound Attenuation | Can help reduce noise pollution in urban areas when used in buildings. |

| Eco-Friendliness | Manufactured from recyclable materials, contributing to sustainability efforts. |

| Cost-Effectiveness | Lower maintenance costs due to their durability and resistance to environmental factors. |

| Security | Provides a layer of security while still allowing visibility and light through. |

| Custom Manufacturing | Can be tailored to specific sizes and needs, enhancing unique architectural features. |

Perforated metal screens offer notable economic benefits. Often used in various industries, they are cost-effective solutions for architects and manufacturers alike. They provide a practical approach to material usage, minimizing waste while maximizing functionality. According to recent industry reports, perforated metals can reduce costs by up to 30% over traditional materials.

The versatility of these screens allows for numerous applications. For instance, they serve as effective filters, enclosures, and noise barriers. This flexibility means businesses can adapt to changing needs without the burden of heavy financial investment. Additionally, using perforated screens can enhance energy efficiency. Studies have shown that installations can result in energy savings of 15% to 20%, leading to lower long-term operational expenses.

Tips: Consider using these screens in ventilation systems. They aid airflow while ensuring structural integrity. Be mindful of the gauge and hole size selection; it can impact both function and appearance. This foresight can prevent costly adjustments later. Proper planning is key.