In the realm of modern construction, the choice of materials plays a pivotal role in the functionality and aesthetic appeal of any project. Perforated Steel Panels, celebrated for their versatility and strength, have gained immense popularity among architects and builders alike. According to Dr. Marie Johnson, a renowned expert in structural engineering, "The unique properties of Perforated Steel Panels not only enhance the design but also improve the overall performance of a structure." This quote underscores the importance of understanding both the technical and artistic aspects of using these panels.

When selecting and installing Perforated Steel Panels, it is essential to consider various factors, including the unique patterns, the thickness of the material, and the intended application. Whether utilized for facades, interior partitions, or sun shading, the right choice can significantly impact energy efficiency and aesthetic value. In this guide, we will delve into the key considerations in choosing the appropriate Perforated Steel Panels for your construction projects, as well as detailed installation procedures to ensure lasting quality and performance. By following expert recommendations and best practices, one can achieve structures that are not only visually striking but also functionally superior.

Selecting the right perforated steel panels for your construction project requires careful consideration of several key factors. First, you must assess the functional requirements of your project. Different applications—such as facade cladding, screens, or sunshades—demand specific panel characteristics, including hole size, pattern, and material thickness. For example, larger holes may enhance ventilation but reduce privacy, while intricate patterns can provide aesthetic appeal while serving functional needs.

Furthermore, understanding the environmental conditions in which the panels will be used is crucial. Exposure to elements like moisture, salt, or sunlight can affect durability and appearance over time. Choosing corrosion-resistant finishes and robust materials can significantly extend the lifespan of your panels. Finally, don't overlook the importance of matching the perforated steel panels with the overall design and architectural style of your project. Ensuring that the panels harmonize with the surrounding structure not only enhances visual appeal but also contributes to the project's overall value and coherence.

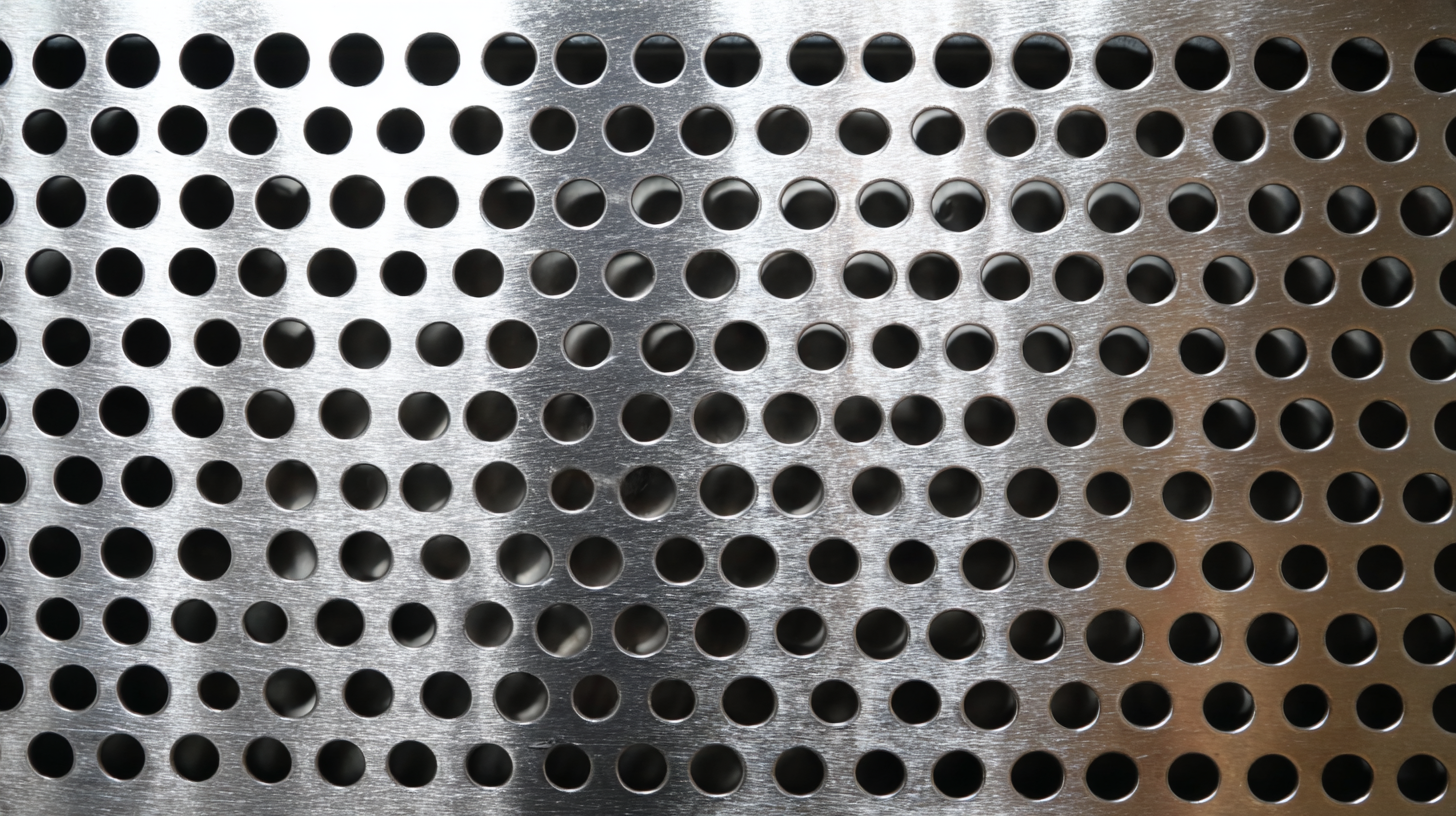

When selecting perforated steel panels for construction projects, it's crucial to understand the various types available on the market. Perforated steel panels can differ significantly based on their hole patterns, sizes, and configurations. Common designs include round, square, and slotted holes, each serving different aesthetic and functional purposes.

For instance, round holes may be preferred for a sleek, modern look, while slotted options can allow for better drainage or airflow, making them suitable for external facades or privacy screens.

Furthermore, the thickness and material grade of the steel also play a vital role in determining the durability and application of the panels. Thicker panels can provide enhanced structural support, making them ideal for heavy-use environments, while thinner variants might be better suited for decorative applications where weight and flexibility are priorities. Understanding these distinctions not only aids in aesthetic matching but also ensures that the selected panels meet the project's specific performance criteria, such as load-bearing capacity and corrosion resistance.

When it comes to installing perforated steel panels, careful measurement and planning are critical to achieving a successful outcome. Start by accurately assessing the area where the panels will be installed. Use a reliable measuring tape and take multiple measurements to confirm dimensions. Pay attention to any irregularities in the surface that may require adjustments to the panel sizes. Documenting these measurements will help you create a detailed plan and avoid costly mistakes during installation.

Next, consider the spacing and layout of the panels. Think about how they will interact with the surrounding elements, including structural supports and other architectural features. Create a scale drawing to visualize the arrangement of the panels, ensuring that the design meets both aesthetic and functional requirements. Additionally, factor in the installation process itself—determine whether you will need specialized tools or additional personnel to assist with the heavy lifting and precise placement of the panels. By meticulously measuring and planning every aspect of your installation, you can ensure a smooth process and a visually appealing result.

When installing perforated steel panels, having the right tools and materials is crucial for a successful outcome. Key tools include power drills with various bit sizes for making precise holes, a level for ensuring alignment, and saws for cutting panels to fit specific dimensions. Safety should not be overlooked; proper personal protective equipment (PPE) such as gloves, goggles, and masks is essential to safeguard against debris and sharp edges during installation.

In terms of materials, high-quality perforated steel panels are available in various gauges, sizes, and hole patterns. According to a report by the Steel Construction Institute, the use of perforated steel can increase the aesthetic appeal of structures while maintaining functional integrity. When selecting panels, consider factors like corrosion resistance and load-bearing capacity, especially in areas prone to harsh weather conditions.

**Tips:** Always double-check the measurements before cutting panels to minimize waste. Additionally, consulting manufacturer specifications can provide insights into the best practices for installation and maintenance, ensuring longevity in your construction projects. Remember, proper installation not only enhances aesthetics but also contributes to the durability of the structure.

| Dimension | Material | Tools Required for Installation | Installation Steps |

|---|---|---|---|

| 4’ x 8’ | Galvanized Steel | Drill, Level, Screwdriver, Measuring Tape | 1. Measure area 2. Cut panels 3. Drill holes 4. Secure panels |

| 3’ x 3’ | Stainless Steel | Wrench, Bolt Cutter, Level, Hammer | 1. Prepare surface 2. Align panels 3. Install fasteners 4. Finishing touch |

| 2’ x 4’ | Aluminum | Saw, Drill, Safety Goggles, Level | 1. Mark locations 2. Cut to size 3. Attach brackets 4. Hang panels |

| 5’ x 10’ | Mild Steel | Drill, Circular Saw, Ladder, Level | 1. Inspect area 2. Cut metal panels 3. Drill mounting holes 4. Install panels |

When installing perforated steel panels, avoiding common pitfalls is crucial for achieving optimal results. One frequent mistake is neglecting proper measurements. Accurate measurements ensure that panels fit seamlessly into a project's specifications. Failing to measure correctly can lead to costly adjustments and delays, complicating the construction timeline. It's essential to double-check all dimensions before proceeding with the installation to prevent these issues.

Another common error is overlooking the importance of selecting the right tools and materials. Using inappropriate tools can lead to uneven cuts or damage to the panels, compromising their structural integrity. Additionally, not considering the panel’s environmental exposure may result in premature deterioration. Ensuring that the chosen steel panels are suitable for the specific conditions they will face is vital for long-term durability. By being mindful of these mistakes, contractors can enhance the effectiveness of their installation and ensure the success of their construction projects.