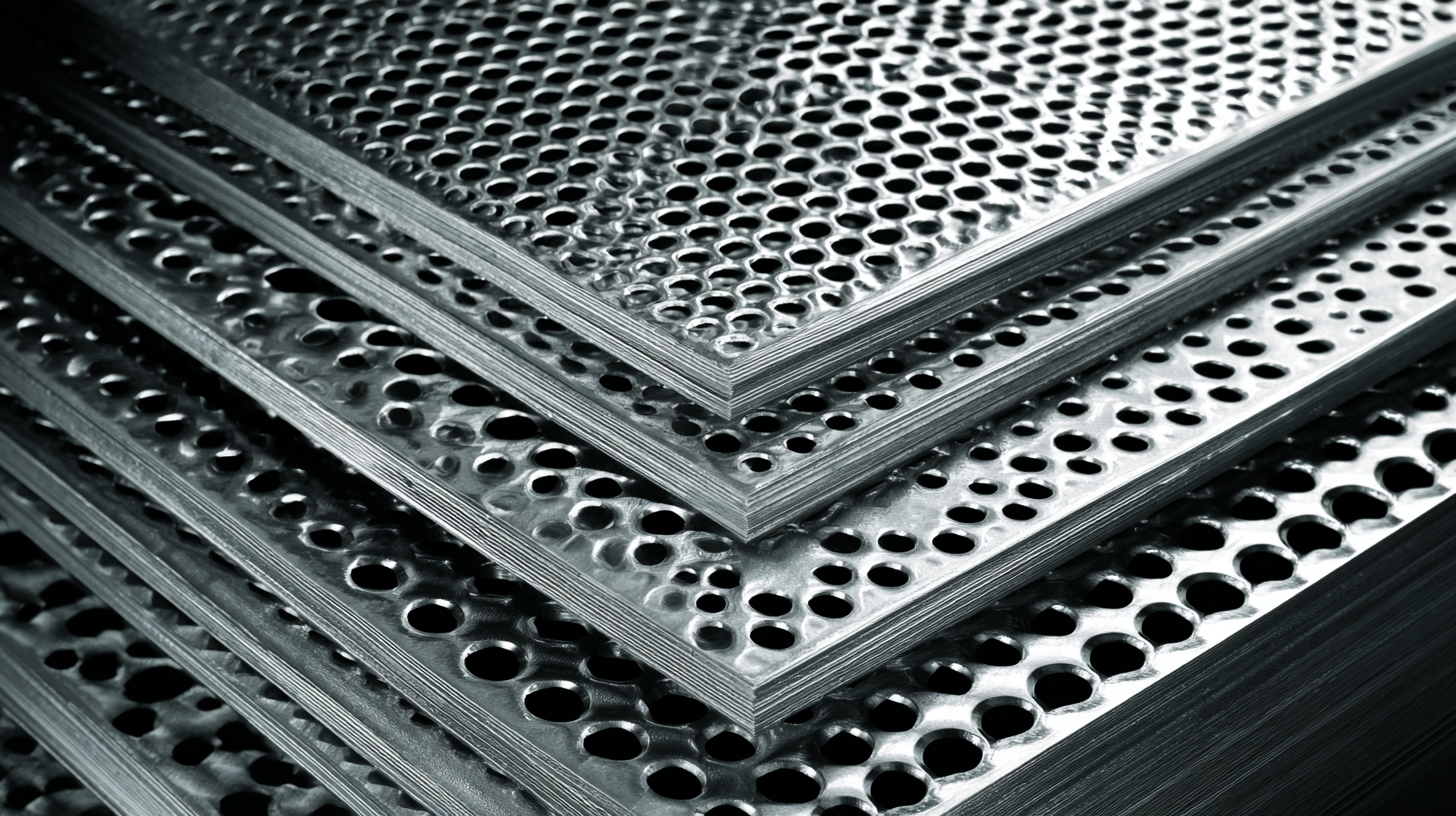

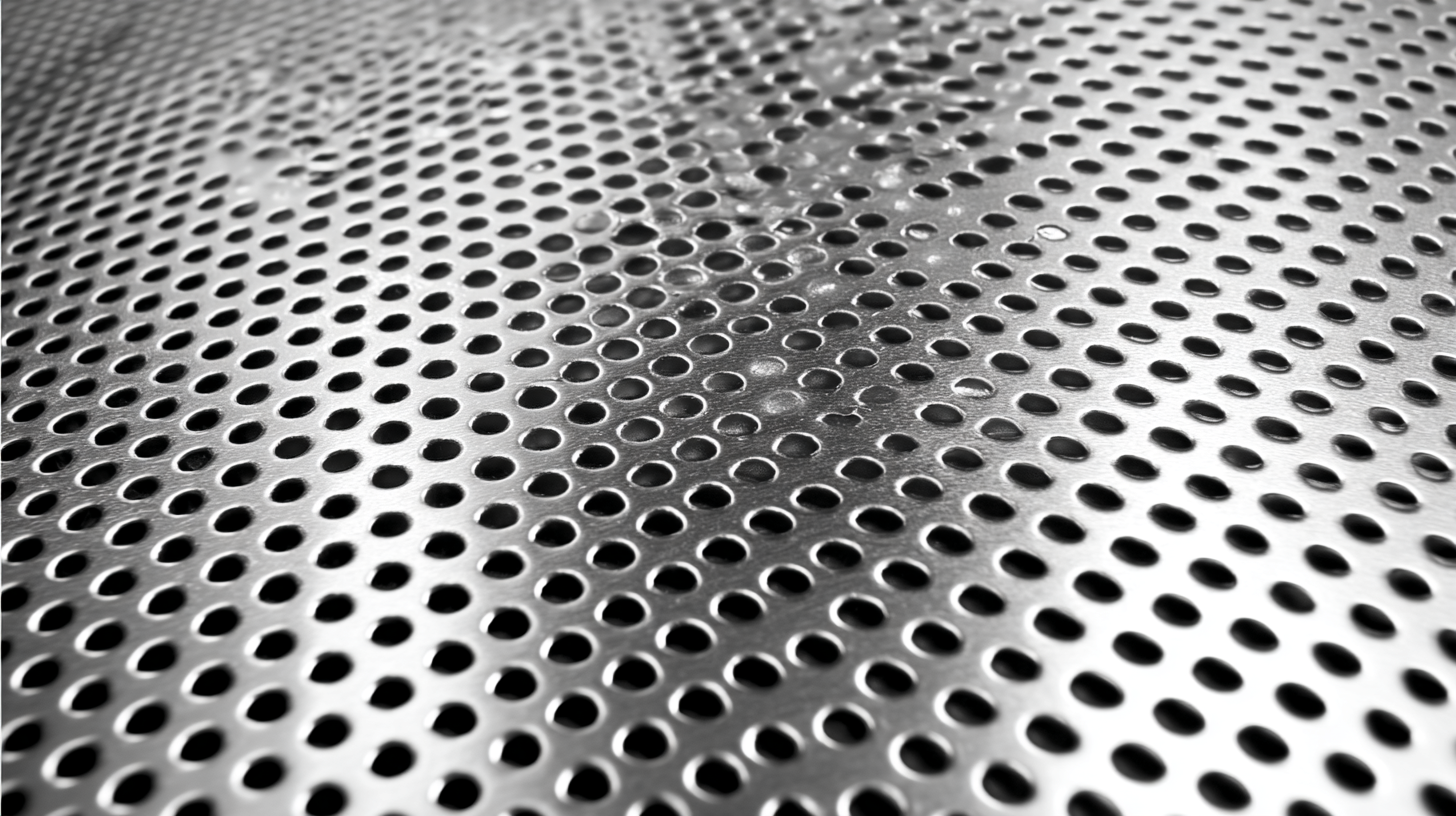

Choosing the right materials for your project can significantly impact its overall success, and when it comes to functional and aesthetic applications, a Stainless Perforated Sheet stands out as a versatile option. Whether you're designing architectural features, creating industrial filters, or fabricating custom furniture, understanding the various attributes of Stainless Perforated Sheets is essential. This guide aims to provide you with key insights into selecting the most suitable type for your specific needs. From considering the sheet's thickness, hole size, and pattern to understanding its corrosion resistance and durability, making an informed choice can elevate your project to new heights. Join us as we explore the crucial factors in choosing the ideal Stainless Perforated Sheet that not only meets your technical requirements but also aligns with your design vision.

When selecting a stainless perforated sheet for your project, it’s essential to understand the different grades of stainless steel available. The most common grades include 304 and 316, each suitable for various applications.

Grade 304 is known for its excellent corrosion resistance and is perfect for indoor environments and projects that don't face extreme conditions. In contrast, grade 316 offers superior resistance to salt and harsh chemicals, making it ideal for marine applications or locations exposed to corrosive elements.

When selecting a stainless perforated sheet for your project, it’s essential to understand the different grades of stainless steel available. The most common grades include 304 and 316, each suitable for various applications.

Grade 304 is known for its excellent corrosion resistance and is perfect for indoor environments and projects that don't face extreme conditions. In contrast, grade 316 offers superior resistance to salt and harsh chemicals, making it ideal for marine applications or locations exposed to corrosive elements.

Tips: Always consider the environment where the perforated sheet will be installed. If it’s near the ocean or exposed to chemicals, opt for grade 316. For indoor, less demanding applications, grade 304 usually suffices.

Additionally, pay attention to the thickness and hole size of the perforated sheet. Thicker sheets can support more weight and provide better durability, while the size and pattern of the holes can significantly impact airflow and aesthetics. Matching these specifications to the project's requirements is crucial for achieving optimal functionality.

Tips: Evaluate both structural and visual needs when choosing hole patterns. A larger hole may improve ventilation, but it could also reduce the sheet's strength, so find a balance that works for your specific project.

When selecting a stainless perforated sheet for your project, understanding the significance of perforation size and pattern is crucial. The size of the holes can dramatically affect the material's strength and functionality. For instance, smaller perforations tend to offer better load-carrying capacities, particularly in applications like cold-formed steel cantilever beams, where structural integrity is paramount. According to industry reports, adjusting perforation sizes can lead to a capability-to-weight ratio improvement of up to 30%, making it essential to align your project's requirements with the sheet's specifications.

Tips: Always consider the load-bearing requirements of your application before finalizing the perforation dimensions. Testing the structural performance of various patterns can help identify the optimal design. Different patterns not only serve aesthetic purposes but also influence airflow and light transmission, which might be pivotal for architectural applications.

Also, keep in mind the ecological implications of your material choices. The ongoing discussions around the late-Quaternary megafauna extinctions highlight the importance of sustainable sourcing and eco-conscious manufacturing in the materials industry. Selecting perforated stainless steel that adheres to sustainable practices can enhance your project's overall impact.

When evaluating the strength and durability requirements for your project, it is essential to consider the specific application and environmental conditions the stainless perforated sheet will face. According to a report by the Stainless Steel Council, stainless steel's inherent corrosion resistance makes it an ideal choice for applications exposed to moisture or chemicals, particularly in industries such as construction and food processing. For instance, 304 and 316 grades are commonly used due to their robust mechanical properties and resistance to rust, with 316 stainless steel offering superior performance in saline environments.

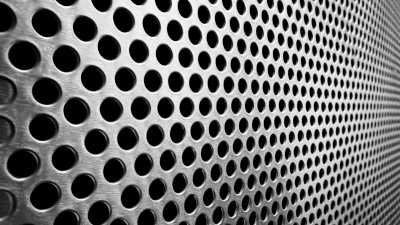

Another crucial aspect is the sheet's perforation pattern and percentage of open area. A study published by the Metal Construction Association indicates that the open area directly influences airflow and load-bearing capabilities. For projects requiring high strength paired with lightweight materials, a perforated sheet with a lower open area may deliver better structural integrity. Furthermore, evaluating load capacity against industry standards ensures the chosen material meets necessary safety and performance requirements. Understanding these factors can significantly impact the longevity and functionality of your project, making it vital to align your material choice with specific durability needs.

| Material Grade | Hole Size (mm) | Thickness (mm) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| 304 Stainless Steel | 3 | 1.2 | Moderate | Food Processing, Chemical Equipment |

| 316 Stainless Steel | 5 | 1.5 | High | Marine Applications, Pharmaceutical |

| 430 Stainless Steel | 4 | 0.8 | Moderate | Decorative Applications, Exhaust Systems |

| Duplex Stainless Steel | 2 | 1.5 | Very High | Oil and Gas, Chemical Processing |

When selecting stainless perforated sheets for your project, corrosion resistance is a critical factor to consider. Stainless steel is inherently more resistant to corrosion than other materials, thanks to its alloying elements such as chromium, which forms a protective oxide layer. This property makes it ideal for a variety of applications, especially in environments subject to moisture or chemicals.

The global perforated metal sheets market is anticipated to grow significantly, with projections suggesting an increase from USD 2.9 billion in 2025 to USD 5.3 billion by 2035, reflecting a compound annual growth rate (CAGR) of 6.2%. This growth can be attributed to the rising demand for materials that can withstand harsh conditions without compromising structural integrity. Investors and manufacturers alike are prioritizing corrosion-resistant options, ensuring longevity and reducing maintenance costs.

**Tips:** When choosing a stainless perforated sheet, assess the specific environment it will be used in; look at factors like humidity, temperature, and potential chemical exposure. Additionally, consider the perforation pattern and size, as they can affect not only aesthetics but also the material’s functionality and resistance to corrosion. Finally, always verify the grade of stainless steel you are using; higher grades may offer enhanced resistance in more aggressive environments.

When sourcing stainless perforated sheets for your project, it's essential to compare suppliers carefully to ensure you get the best quality and value. Start by identifying your specific requirements, such as hole size, sheet thickness, and finish. This will help you narrow down suppliers who specialize in the type of perforated sheets you need.

One key tip is to request samples from different suppliers. This allows you to assess not only the quality of the material but also the precision of the perforations. Look for suppliers that offer customizable options, as this flexibility can be crucial depending on the unique demands of your project. Additionally, check reviews or ask for references to gauge their reliability and customer service.

Lastly, don't forget to consider pricing, but remember that the cheapest option isn’t always the best. Evaluate the total cost, including shipping and potential setup fees. Some suppliers may offer bulk discounts or loyalty programs that could lead to savings in the long run. A thorough comparison will help you find the right supplier and ensure the success of your project.