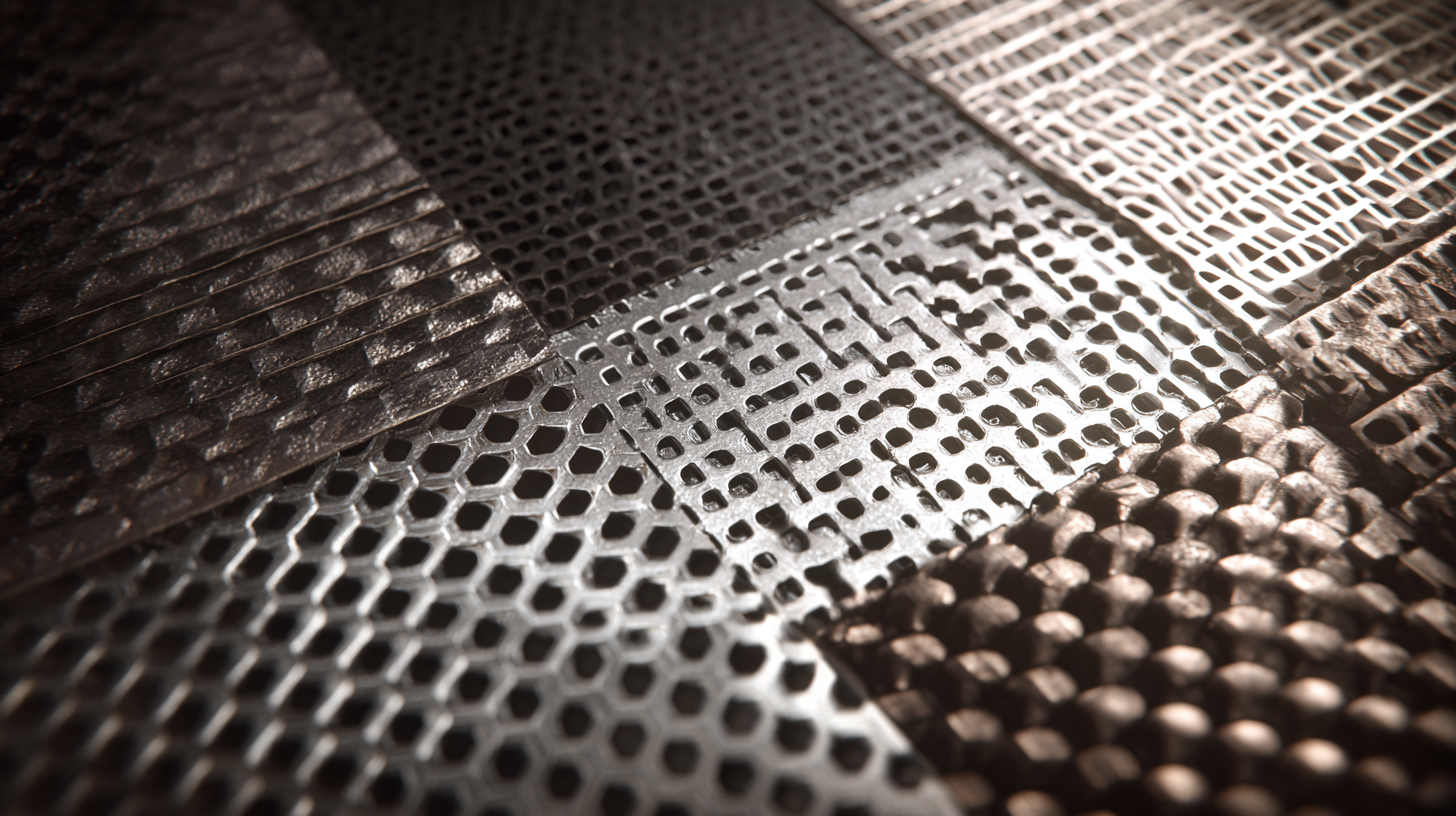

In the rapidly evolving landscape of global supply chains, the significance of high-quality materials cannot be overstated. Among these, Punched Metal Sheets have emerged as a pivotal component, driving innovations across various industries from automotive to construction.

According to a recent report by Grand View Research, the global metal fabrication market is expected to reach USD 267.6 billion by 2025, with a substantial share attributed to punched metal products due to their versatility and strength. As manufacturers seek to enhance efficiency and reduce costs, leveraging the finest punched metal sheets from China presents a strategic advantage.

This blog will explore top strategies for integrating these exceptional materials into supply chains, ensuring competitiveness and sustainability in a market that demands both quality and agility.

China has long been recognized as a global manufacturing powerhouse, and its punched metal sheets are a testament to this reputation. With an unwavering commitment to quality, Chinese manufacturers have harnessed advanced technologies and skilled craftsmanship to produce metal sheets that meet international standards. Companies sourcing from China can confidently rely on the consistency and durability of these products, which enhances their supply chain resilience.

The punched metal sheets industry is witnessing a surge in global trust, particularly among businesses prioritizing sustainability and efficiency. By utilizing innovative designs and eco-friendly materials, Chinese manufacturers are positioning themselves at the forefront of environmentally responsible production. This shift not only appeals to conscientious consumers but also opens new avenues for partnerships across the globe, reinforcing the importance of trust in fostering long-term supplier relationships. As industries evolve, the ability of China’s punched metal sheets to adapt to specific needs will continue to solidify their role in empowering global supply chains.

Innovative manufacturing processes have revolutionized the production of punched metal sheets, making them a cornerstone of modern supply chains. In China, cutting-edge technologies such as laser cutting, automated stamping, and precision machining are employed to enhance efficiency and reduce waste in production lines. These advancements not only streamline operations but also ensure that the punched metal sheets meet the highest quality standards, providing significant value to manufacturers worldwide.

Moreover, the integration of Industry 4.0 principles in punched metal sheet production facilitates real-time monitoring and data analytics. This enables manufacturers to predict maintenance needs, optimize workflows, and significantly improve turnaround times. By leveraging automation and smart technologies, Chinese manufacturers are able to produce custom designs quickly and efficiently, catering to diverse industry demands from automotive to construction. The result is a robust and agile supply chain that empowers companies globally, instilling confidence in the durability and reliability of the materials they source.

Punched metal sheets are becoming increasingly significant in the global supply chain landscape. Their versatility and robustness make them essential for a multitude of applications, including construction, automotive, and consumer products. Recent market research indicates a growing trend in the adoption of perforated materials, which can enhance efficiency and reduce waste within supply chains. Key statistics reflect an upward trajectory in the demand for these sheets, driven by their ability to support eco-friendly practices as industries pivot towards sustainability.

To effectively leverage punched metal sheets in supply chains, businesses should consider the following tips: First, assess the specific requirements of your application to choose the right material type. For instance, understanding whether your project needs higher durability or biodegradability can influence your selection process. Second, integrating these materials can significantly improve various functions such as water conservation and temperature regulation, making them suitable for agricultural applications. Lastly, staying updated on market trends will enable companies to align their sourcing strategies with technological advancements and environmental initiatives.

By prioritizing these factors, organizations can not only strengthen their supply chains but also contribute to a more sustainable future.

| Dimension (mm) | Material Type | Thickness (mm) | Applications | Annual Production (tons) |

|---|---|---|---|---|

| 1000 x 2000 | Aluminum | 2 | Automotive, HVAC | 50,000 |

| 1200 x 2400 | Stainless Steel | 1.5 | Construction, Appliances | 30,000 |

| 1500 x 3000 | Mild Steel | 3 | Industrial Equipment | 70,000 |

| 2000 x 4000 | Brass | 1 | Electronics, Decorative | 20,000 |

| 1000 x 1000 | Aluminum Alloy | 2.5 | Aerospace, Marine | 15,000 |

In the fast-evolving landscape of global supply chains, the significance of quality assurance and certifications in metal sheet production cannot be overstated. China, being one of the largest manufacturers of punched metal sheets, has made considerable advancements to meet international standards. According to a report by the International Organization for Standardization (ISO), China’s ISO 9001 certification rate in manufacturing has reached over 50%, indicating a strong commitment to quality management systems. This certification provides manufacturers with the framework to improve efficiency and customer satisfaction, thus elevating the overall standard of their products.

Moreover, compliance with environmental standards has become increasingly important. The Chinese government's push for adherence to ISO 14001 environmental management standards has seen over 23,000 metal manufacturers obtaining certification, reflecting a growing commitment to sustainability. The adoption of these standards helps in ensuring that the production processes are not only efficient but also environmentally responsible, reassuring global partners of their commitment to sustainable industrial practices. As global supply chains become more interconnected, these quality assurances are paramount in facilitating trust and reliability across borders.

In recent years, the demand for eco-friendly practices in manufacturing has become a vital focus for industries worldwide, including the punched metal sheets sector in China. This shift is driven by the global call for sustainability and the need to reduce the environmental impact of production processes. Chinese manufacturers are increasingly adopting green technologies, from using recycled raw materials to implementing energy-efficient production methods. Such innovations not only minimize waste but also significantly lower carbon emissions, aligning with global sustainability goals.

Moreover, many companies are seeking certifications that demonstrate their commitment to sustainable practices. By adhering to stringent environmental standards, Chinese punched metal sheet manufacturers are positioning themselves favorably in the global market. These eco-friendly practices not only enhance the quality of their products but also build trust and loyalty among environmentally conscious consumers and businesses. As a result, China's punched metal sheets industry is not just becoming a leader in quality and innovation but is also setting an example of how manufacturing can evolve to meet the challenges of sustainability.