In the ever-evolving landscape of architectural and manufacturing design, the use of Perforated Metal Plate has gained significant traction due to its myriad benefits. According to a report by Research and Markets, the global perforated metal market is projected to reach over $5 billion by 2027, reflecting a growing recognition of its versatility and functionality. From enhanced aesthetic appeal to improved acoustic performance, Perforated Metal Plates are revolutionizing the way designers and engineers approach their projects. This innovative material not only offers a unique blend of strength and lightweight characteristics but also promotes sustainability by often being manufactured from recyclable materials. As industries increasingly seek to balance performance with environmental impact, understanding the incredible benefits of Perforated Metal Plate becomes crucial for anyone looking to elevate their project outcomes.

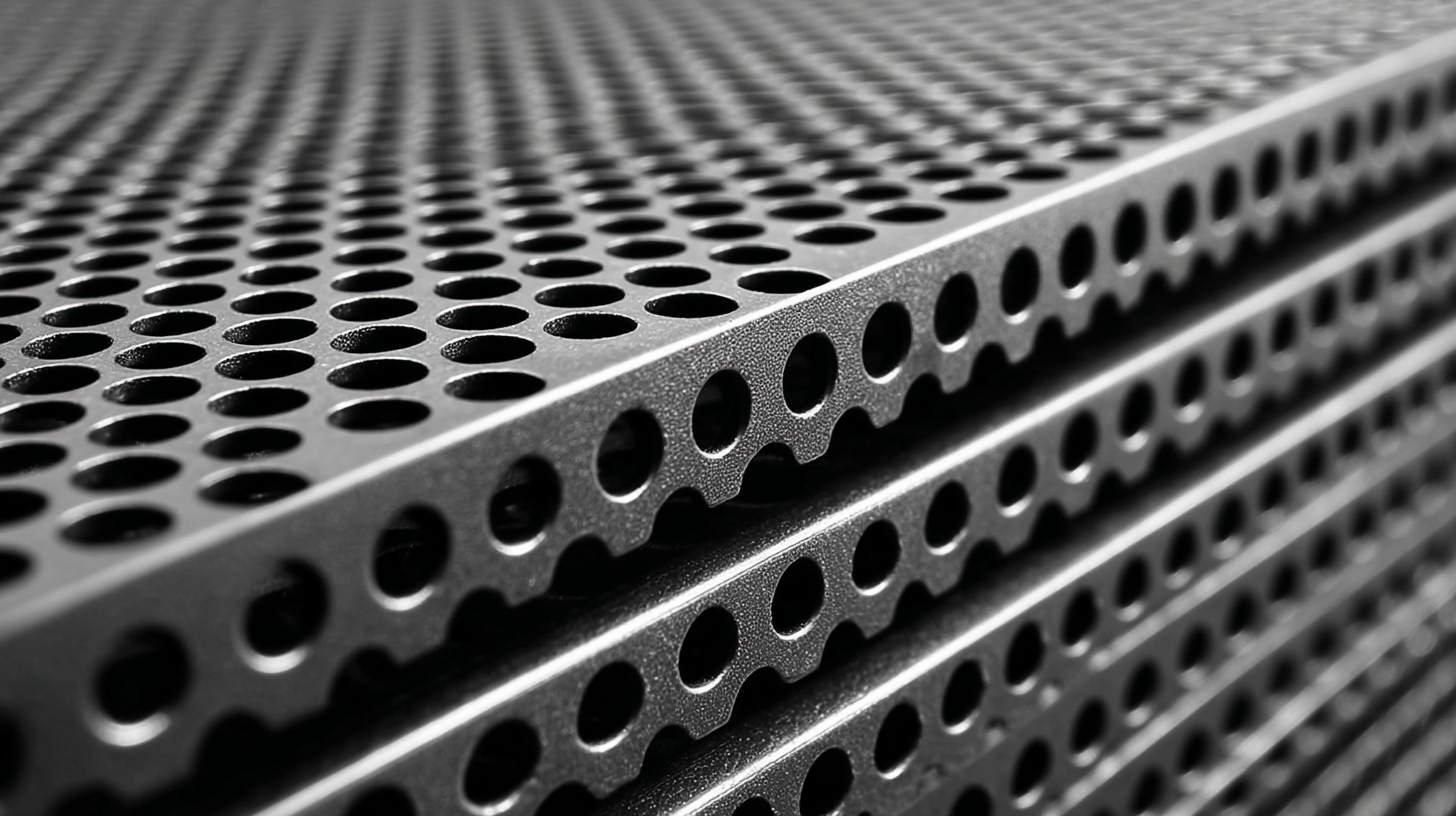

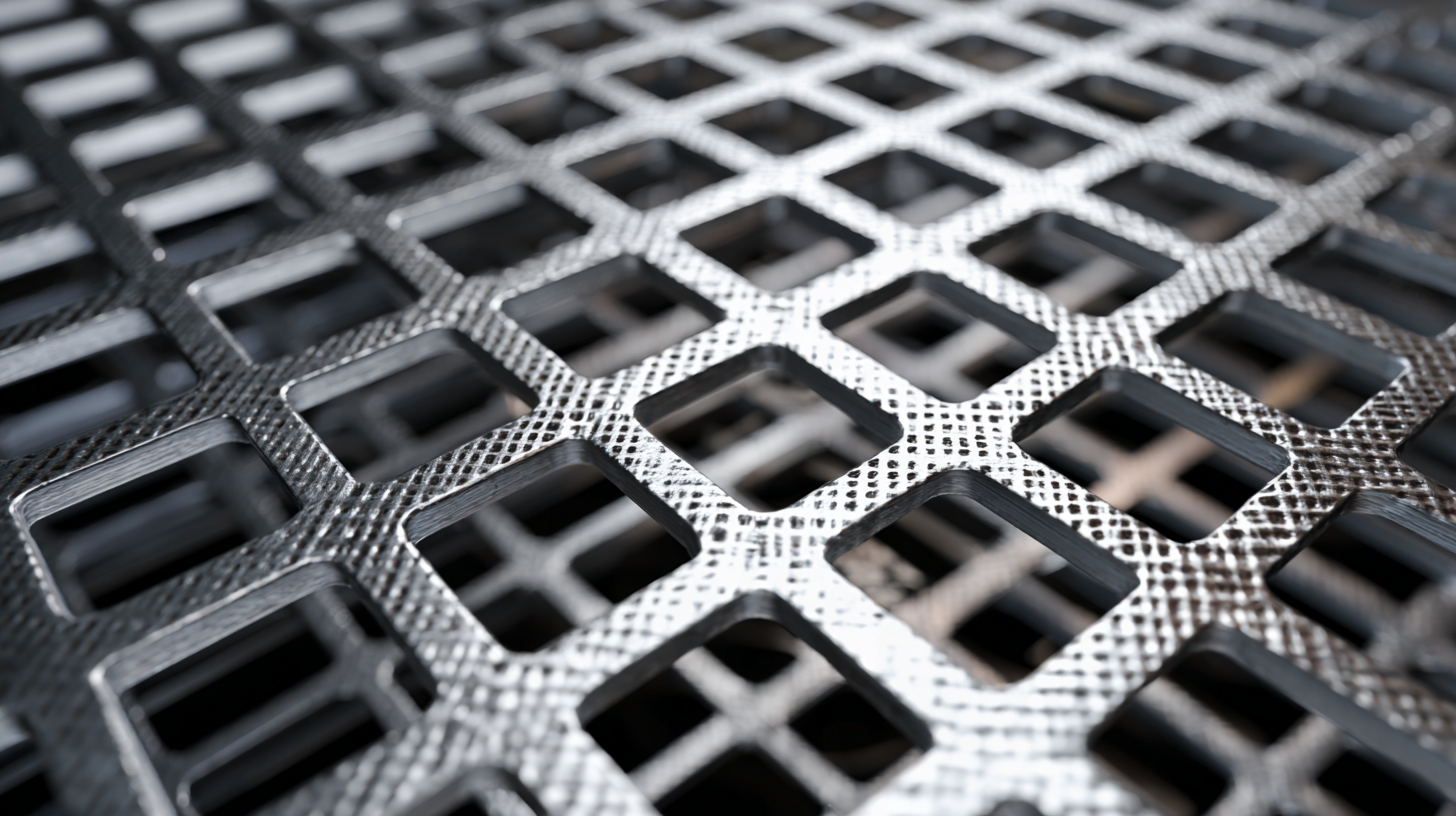

Perforated metal plates have emerged as a key material in modern design applications, thanks to their unique combination of aesthetic appeal and functional utility. These versatile sheets, featuring an array of holes with varying patterns and sizes, offer endless design possibilities, allowing architects and designers to create striking visual elements in their projects. From facades to interior partitions, the ability to manipulate light and shadow through perforation adds depth and character, enhancing the overall aesthetic experience of a space.

Perforated metal plates have emerged as a key material in modern design applications, thanks to their unique combination of aesthetic appeal and functional utility. These versatile sheets, featuring an array of holes with varying patterns and sizes, offer endless design possibilities, allowing architects and designers to create striking visual elements in their projects. From facades to interior partitions, the ability to manipulate light and shadow through perforation adds depth and character, enhancing the overall aesthetic experience of a space.

Moreover, the adaptability of perforated metal plates extends beyond mere decoration. They serve practical purposes, such as enhancing airflow and acoustics in various environments, making them ideal for both commercial and residential settings. In landscaping, these plates can be used for trellises or screening, seamlessly blending nature with industrial design. Their durability ensures longevity even in demanding conditions, while the lightweight nature of the material facilitates easier installation. As modern design continues to evolve, perforated metal plates stand out as a functional yet stylish choice, bridging the gap between innovative design and practical application.

Perforated metal plates have emerged as a transformative element in architectural design, contributing not only to functionality but also to the aesthetic appeal of spaces. The unique patterns and versatility of perforated metal allow designers to create visually striking facades, panels, and screens that can redefine an environment. According to a recent report by the Metal Building Manufacturers Association (MBMA), the use of perforated metal in construction has increased by 25% over the past five years, highlighting its growing popularity among architects and builders.

The perforation patterns can be customized to control light, airflow, and sound, enhancing both the utility and beauty of a space. For instance, a well-designed perforated metal screen can serve as a sunshade, reducing heat gain while simultaneously adding an element of intrigue to the exterior design.

**Tips:** When selecting perforated metal plates for your project, consider the size and shape of the holes, as these can impact the visual effect and performance. Additionally, think about the finish of the metal; powder coating can offer both protection and an array of color options to complement your design. Lastly, ensure that the design aligns with the overall theme of your project to achieve a cohesive look.

Perforated metal plates have gained popularity in various industries, and their cost-effectiveness makes them a smart investment for projects of all sizes. With their ability to combine functionality and aesthetic appeal, these plates can significantly reduce material costs while providing excellent performance. The manufacturing process ensures that even customized designs can be produced efficiently, allowing for greater flexibility in your projects without stretching the budget.

When considering perforated metal plates, it’s essential to evaluate your project’s specific needs. **Tip 1:** Determine the required perforation pattern early on to optimize both strength and weight, ensuring that the final product meets your performance and aesthetic criteria. **Tip 2:** Compare different material options; aluminum, steel, and stainless steel can all offer unique benefits that affect both the cost and durability of your project. By carefully planning and selecting the right materials, you can enhance the overall value of your investment.

Additionally, the versatility of perforated metal allows for integration into various applications—from architectural facades to functional screens. **Tip 3:** Always account for additional costs related to installation and maintenance, as these factors can influence the overall cost-effectiveness of using perforated metal plates. Being proactive in your planning will safeguard against budget overruns and ensure your project stays on track.

This chart illustrates the various benefits of using perforated metal plates in projects, highlighting their cost-effectiveness, weight reduction, aesthetic appeal, and other advantages on a scale of 1 to 10.

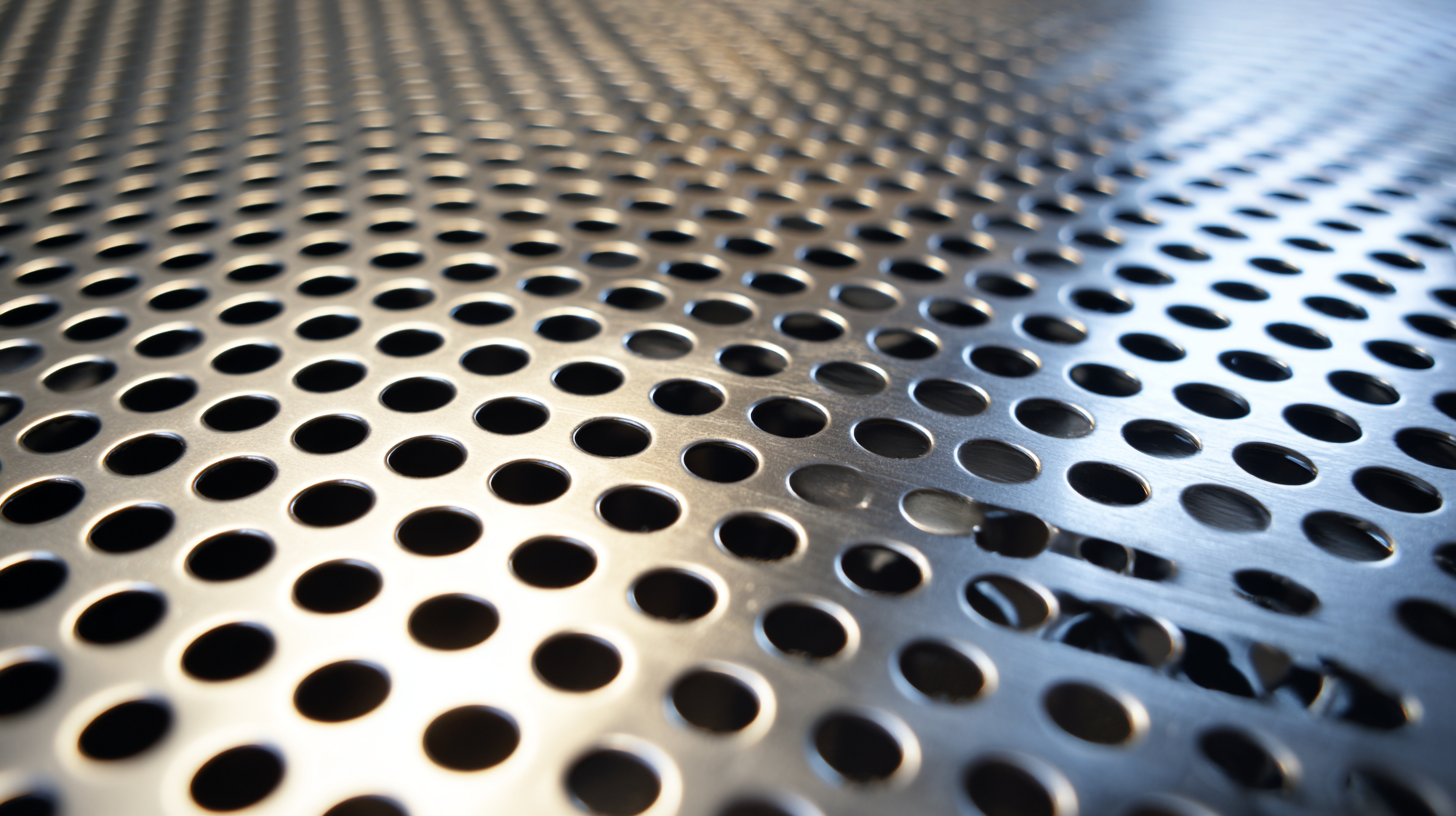

Perforated metal plates are becoming increasingly popular in sustainable construction due to their eco-friendly benefits. These plates not only enhance the aesthetic appeal of a project but also provide crucial structural advantages. By using materials that can be recycled and repurposed, builders contribute to reducing waste and promoting sustainability in construction practices.

One key advantage of perforated metal plates is their ability to support ventilation and natural lighting, which reduces the need for artificial lighting and air conditioning. This not only lowers energy consumption but also improves the overall environment within a building, promoting well-being among occupants. When designing with perforated metal, consider integrating it into areas where airflow is essential, such as facades or ceilings, to maximize its benefits.

Additionally, the use of perforated metal plates aligns with modern environmental protection standards. Incorporating these elements can significantly enhance a project's appeal while fulfilling the growing demand for sustainable solutions in architecture. When planning your next project, explore the versatility of perforated metal plates, ensuring that your design is both functional and environmentally friendly.

Perforated metal plates are revolutionizing design and construction, enhancing both safety and functionality in various applications. According to a report by the Global Perforated Metal Market, the demand for perforated metals is projected to grow by 5.2% annually through 2025, driven by their unique structural advantages. These plates are lightweight yet incredibly strong, providing essential support without adding unnecessary bulk. Their ability to maintain structural integrity under stress makes them ideal for use in building facades, staircases, and safety barriers.

Another significant benefit is their enhanced safety features. Perforated metal plates provide better airflow and reduce the risk of heat buildup in environments that require ventilation, such as industrial facilities and commercial spaces. A study from the American Institute of Steel Construction highlights that using perforated sheets can improve visibility and reduce accidents in architectural installations. This functionality translates into a safer workplace, as the design allows for proper light diffusion while maintaining privacy and security for occupants. Integrating perforated metal plates into projects can significantly boost both aesthetic appeal and operational efficiency.