A Metal Sheet With Holes is more than just a flat piece of metal. It has a unique design that features various perforations. These holes can be of different shapes and sizes, depending on their intended use. The presence of holes reduces weight while maintaining strength.

Applications of Metal Sheets With Holes are diverse. They are commonly found in architecture, HVAC systems, and industrial equipment. For example, these sheets can be used as decorative elements in buildings, allowing for creative designs. Additionally, they improve airflow and ventilation in machinery. However, not all uses are without challenges.

Sometimes, the process of creating these sheets can lead to waste. Manufacturing techniques might need refinement. The selection of materials is also crucial. An optimal choice enhances durability but affects cost. Each decision must be carefully considered to balance practicality and functionality.

Metal sheets with holes are engineered materials crafted for specific applications. These sheets are typically made from metals like aluminum, stainless steel, or galvanized steel. The holes can vary in size and spacing, making each sheet unique. For instance, a report from the International Journal of Metal Engineering highlights that sheets with staggered holes are often used in filtration systems. This configuration enhances airflow while reducing material weight.

The characteristics of these sheets are essential for their functionality. They offer excellent strength-to-weight ratios. According to data from the Metal Forming Association, using metal sheets with holes can reduce material costs by 20% to 30% compared to solid sheets. The perforations also allow for better drainage or ventilation. However, some designs can weaken the structural integrity. This often requires careful consideration in high-stress applications, such as construction or automotive industries.

Applications span diverse fields. In architecture, these sheets create unique facades and allow natural light to permeate spaces. In the electronic industry, they serve as heat exchangers. Despite their benefits, the production process can be energy-intensive. Researchers are exploring greener methods to minimize environmental impacts. Understanding these aspects is crucial for making informed design choices.

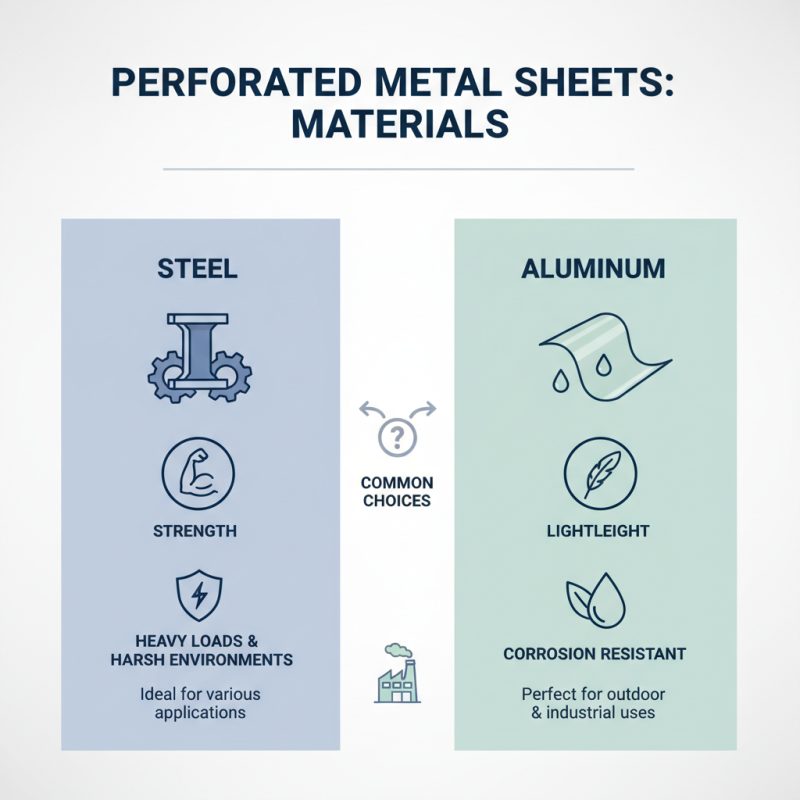

When it comes to manufacturing perforated metal sheets, several materials are commonly used. Steel is one of the most prevalent choices. Its strength and durability make it ideal for various applications. This material withstands heavy loads and harsh environments. Aluminum is another popular option. It is lightweight and resistant to corrosion. This property makes aluminum sheets perfect for outdoor and industrial uses.

Copper is used for its excellent conductivity. It is often found in architectural designs and electronic applications. Stainless steel offers both aesthetics and resistance to rust. This makes it suitable for both functional and decorative purposes. Manufacturers often choose the material based on the specific needs of the project.

While these materials have their advantages, each also presents challenges. Steel can be heavy, making installation difficult. Aluminum, while light, can be prone to bending under heavy loads. Reflecting on material choices is crucial, as it can impact overall functionality and durability. Proper evaluation of each material’s properties is essential in achieving the desired outcome.

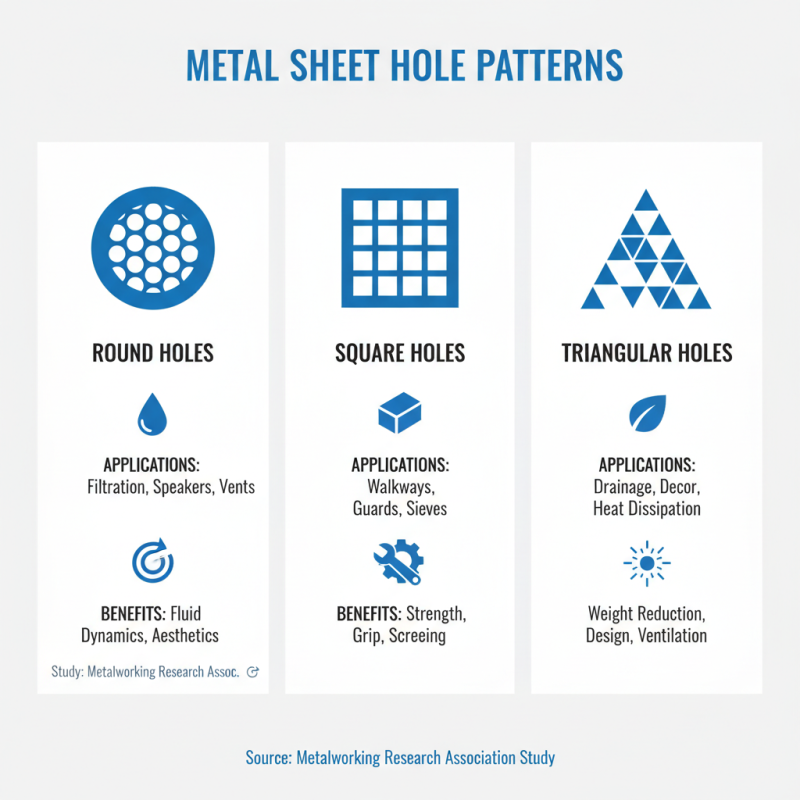

When designing metal sheets with holes, the arrangement and size of those holes play a crucial role. Common hole patterns include round, square, and triangular shapes. The choice of these patterns often depends on the desired airflow, drainage, and aesthetic considerations. For example, a study published by the Metalworking Research Association indicates that circular holes allow for better fluid dynamics, enhancing performance in applications like filtration systems.

Design considerations must also focus on material integrity. Holes weaken the structural support of the sheet when poorly designed. A report from the International Journal of Structural Engineering highlights that irregular patterns can exacerbate stress concentrations, leading to unexpected failures. Designers should aim for consistent spacing and sizing to minimize these risks.

Furthermore, the manufacturing process can affect hole finish quality. Punching can leave burrs that compromise functionality. On the other hand, laser-cut holes may provide precision but at a higher cost. Balancing the method and the final product's purpose is essential. Continuous reflection on these aspects can refine designs and improve longevity.

Metal sheets with holes are crucial in many industries. These sheets are commonly used in construction, automotive, and aerospace sectors. They serve functional purposes, such as ventilation and filtration. The perforations allow air or fluids to pass through while maintaining structural integrity.

In construction, metal sheets with holes are used for cladding and roofing. They help manage airflow, reducing heat buildup. In automotive applications, these sheets contribute to the car's lightweight design. However, the choice of hole size and pattern can impact strength. In aerospace, precision and durability are essential. Engineers must consider these factors when selecting materials.

There are downsides to using perforated metal sheets. Sometimes, the manufacturing process can lead to jagged edges. This might require additional finishing work. Moreover, the design might not meet specific end-use requirements. Each industry has unique demands, and balancing those with functionality is challenging. Understanding these applications is vital for successful implementation.

Perforated metal sheets, featuring a variety of hole patterns, play a crucial role in construction and engineering. These sheets are lightweight yet durable. Their unique design allows for effective airflow and drainage, making them ideal for various applications. Architects often choose them for facades and interior designs. The holes can reduce wind resistance, enhancing structural integrity.

Using perforated metal offers specific advantages. It allows for natural light penetration while maintaining privacy. Projects can benefit from reduced energy costs as ambient light is maximized. Additionally, perforated metal is customizable, fitting diverse aesthetics and functional needs. However, selecting the right pattern and thickness requires careful consideration.

Some challenges exist when using perforated metal. It may not always meet the load-bearing needs of certain structures. Proper analysis is essential to avoid potential failures. Customization can also lead to increased production time and costs. Though perforated metal is versatile, it can be overwhelming to navigate the options available. Designers must focus on the balance between form and function, ensuring the chosen solution aligns with project goals.

| Dimension | Material | Hole Size | Application Area | Advantages |

|---|---|---|---|---|

| 4x8 ft | Aluminum | 1/4 in | Architectural facades | Lightweight, corrosion resistant |

| 3x6 ft | Stainless Steel | 3/8 in | Industrial machinery | Durable, high strength |

| 2x4 ft | Mild Steel | 1/8 in | Sound barrier walls | Cost-effective, easy to fabricate |

| 5x10 ft | Copper | 1/2 in | Architectural design | Aesthetic appeal, excellent conductivity |