As the global market for decorative perforated sheet metal continues to expand, it is projected to reach approximately $5.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.3% from 2020 to 2025, according to industry reports. This remarkable growth is driven by the increasing demand in various sectors, including architecture, interior design, and automotive applications. Decorative perforated sheet metal not only enhances aesthetic appeal but also offers functional benefits such as sound absorption and ventilation. With innovative designs and versatile applications emerging, understanding the unique uses of decorative perforated sheet metal will empower global buyers to make informed decisions that align with current market trends and technological advancements.

In the realm of modern interiors, decorative perforated sheet metal is emerging as a revolutionary design element that seamlessly blends aesthetics with functionality. This innovative material can transform ordinary spaces into extraordinary environments. With an array of patterns and designs, from geometric shapes to organic motifs, perforated sheets allow for an exceptional level of creativity. These unique designs not only add character to walls and ceilings but also enhance the acoustic properties of a room, making them a perfect choice for commercial and residential interiors alike.

Moreover, the versatility of decorative perforated sheet metal means that it can be used in various applications, such as room dividers, light fixtures, and furniture accents. By allowing light to filter through while maintaining privacy, these panels create dynamic visual effects that can dramatically alter the mood of a space. Whether used in high-end restaurants, trendy cafes, or chic residences, the incorporation of stylish perforated sheet metal brings a contemporary flair that appeals to global buyers seeking to elevate their interior designs.

This chart illustrates the various innovative applications of decorative perforated sheet metal in modern interiors, highlighting key sectors and their respective usage percentages.

Decorative perforated sheet metal has emerged as a versatile material, prized for its aesthetic appeal and functional versatility across various industries. According to the Metal Industries Research Association, the global perforated metal market is expected to reach approximately $2.3 billion by 2026, driven by growing demand in construction and architectural design.

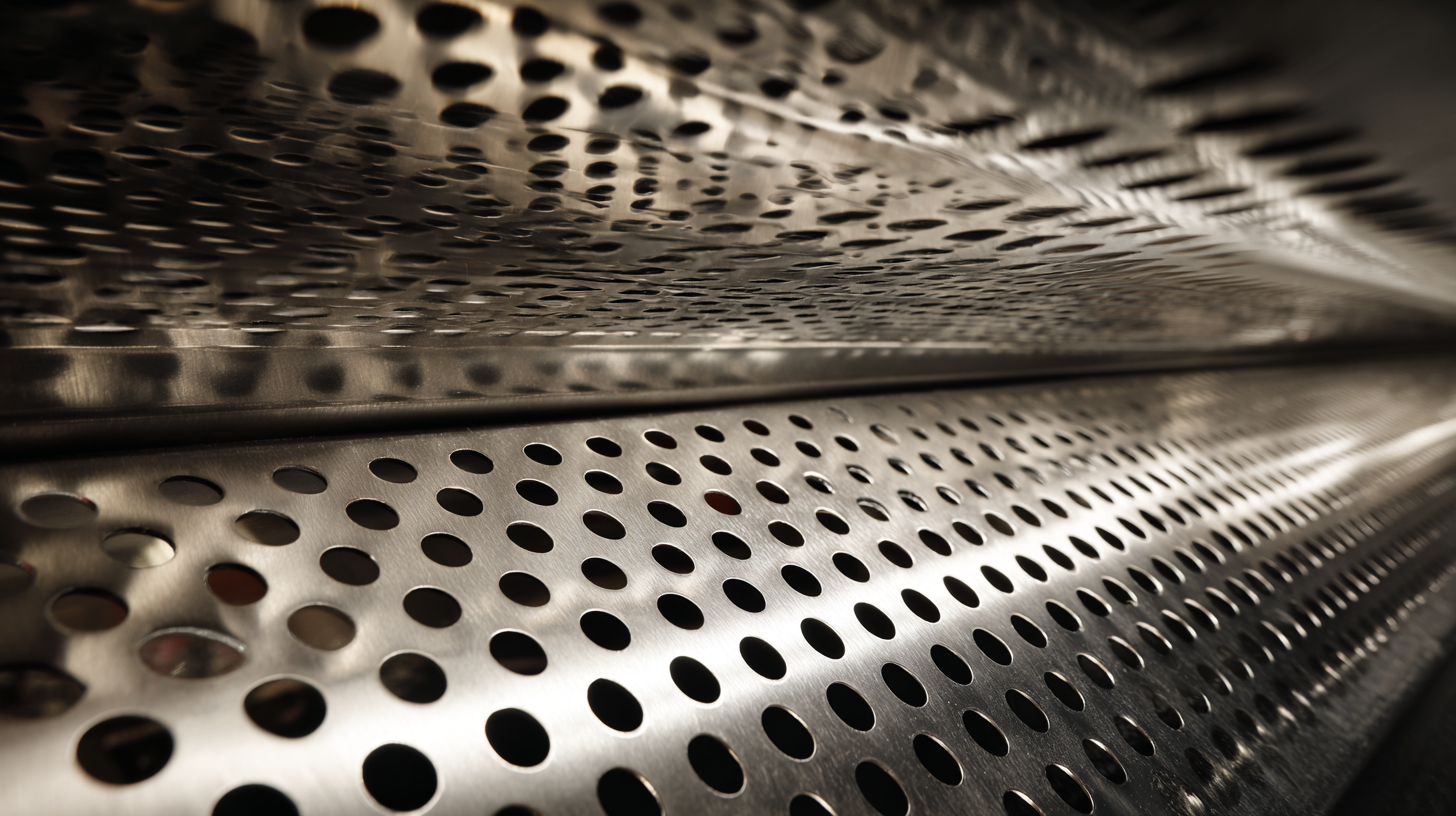

The key characteristics of decorative perforated sheet metal types include variations in hole size, pattern design, and material composition. For instance, sheets with larger holes can enhance light penetration, making them popular in facade applications, while intricate patterns are favored for interior design projects.

Another important attribute to consider is the material used in perforated sheets. Stainless steel, aluminum, and brass are commonly employed, each offering distinct advantages. A report by Smithers Pira indicates that stainless steel accounted for over 40% of the market share in 2023, largely due to its corrosion resistance and longevity, making it ideal for outdoor applications. Additionally, aluminum perforated sheets are valued for their lightweight property and ease of installation, frequently utilized in modern architecture to create dynamic visual effects while enhancing airflow.

Understanding these characteristics allows global buyers to select the best decorative perforated sheet metal for their specific needs and applications.

Decorative perforated sheet metal is gaining traction in construction, particularly as architects and builders seek innovative ways to incorporate aesthetics and functionality into their designs. One of the primary application areas for these materials is in building façades, where they can provide striking visual interest while also enhancing structural integrity. Recent research into the mechanical characterization of double-skin perforated-sheet façades has highlighted their potential to achieve both aesthetic appeal and improved insulation performance, making them a desirable choice in modern architecture.

Another significant area for decorative perforated sheet metal is in interior applications, such as wall panels and ceiling structures. These materials combine lightweight properties with strength and rigidity, which allows for unique design possibilities without compromising safety. Market growth projections indicate that the demand for perforated metal sheets in architectural and industrial contexts will continue to rise through 2035. This trend underscores the increasing recognition of their versatility and the crucial role they play in contemporary design solutions, pushing the boundaries of traditional construction materials.

Choosing the right decorative perforated sheet metal for your project is crucial in achieving both aesthetic appeal and functional performance. When selecting the material, consider factors such as the desired design pattern, hole size, and the thickness of the sheet. A carefully chosen pattern can enhance light modulation, while the right thickness will ensure durability and structural integrity. Moreover, understanding how these sheets will interact with surrounding environments—be it through ventilation or soundproofing—can significantly influence your decision.

Furthermore, it's vital to assess the project's intended use. For instance, if the decorative perforated sheet metal is to be used in outdoor applications, selecting corrosion-resistant materials is essential. Engaging with a trusted supplier can provide insights into the latest trends, techniques, and material innovations in the market. By making informed choices based on your specific requirements and the environment in which the material will be utilized, you can ensure that your decorative sheet not only enhances the visual appeal of your project but also meets practical needs efficiently.

| Application Area | Material Type | Hole Size (mm) | Thickness (mm) | Finish |

|---|---|---|---|---|

| Architectural Facades | Aluminum | 5 | 2 | Powder Coated |

| Interior Partitions | Stainless Steel | 3 | 1.5 | Brushed |

| Ceiling Panels | Mild Steel | 10 | 2.5 | Galvanized |

| Outdoor Privacy Screens | Corten Steel | 7 | 3 | Weathered Finish |

| Acoustic Panels | Aluminum Composite | 4 | 2 | Anodized |

Maintaining decorative perforated sheet metal products is essential to ensure their longevity and aesthetic appeal. One of the primary steps in maintenance is regular cleaning, which helps prevent the accumulation of dirt, dust, and other contaminants. Using a soft cloth or sponge with mild soap and water is effective for routine cleaning. It's crucial to avoid harsh chemicals that can damage the finish or cause corrosion over time. For areas with heavy grease or stubborn stains, a gentle solvent may be used, but it’s essential to test it on a small, inconspicuous area first.

Another important aspect of maintenance is to inspect the perforated sheets periodically for signs of wear, such as scratches, rust, or any form of structural damage. Addressing these issues promptly can prevent more significant problems down the line. If rust does appear, it should be removed quickly with a fine-grit sandpaper or a wire brush, followed by a repainting or application of a protective coating. Finally, storing the sheets properly when not in use—preferably in a dry environment and away from direct sunlight—will further extend their lifespan and keep them looking vibrant.